Views: 0 Author: Site Editor Publish Time: 2025-12-17 Origin: Site

Many PCBA manufacturers invest in X-ray inspection with the right intention — improving quality and reducing escapes — but still end up facing unexpected bottlenecks, rising inspection costs, or delayed feedback when defects occur.

In most cases, the problem is not the X-ray technology itself, but choosing the wrong inspection strategy. Understanding how X-ray inspection works in PCBA manufacturing is often the missing piece when these issues first appear.

Inline and offline X-ray systems serve very different purposes. One is designed to move at the speed of your production line, while the other prioritizes flexibility, resolution, and deep analysis. When the system type doesn’t match your production volume, product mix, or quality requirements, the result can be slower throughput, higher rework costs, or missed defects that only appear after products reach the field.

If you run high-volume SMT lines, an offline X-ray may quickly become a bottleneck. If you produce complex, low-volume boards, an inline system may be underutilized and unnecessarily expensive. In both cases, the wrong choice silently erodes your return on investment — often because defects AOI can’t see but X-ray can are not being captured at the right stage.

Many factories invest in X-ray inspection expecting better quality control, only to find that production efficiency drops after installation. This often happens when an inline X-ray is placed on a line that does not have stable takt time or consistent product flow.

Boards begin to queue in front of the X-ray, operators intervene manually, and the system becomes a bottleneck rather than a safeguard. Over time, production planners start bypassing the inspection step to keep shipments on schedule. At that point, the X-ray system exists on the line, but its real value is no longer realized.

Different products carry very different inspection risks, yet many factories apply a single inspection approach to all boards. High-density boards with BGAs and bottom-terminated components require detailed void and joint analysis, while simpler boards may only need basic pass/fail checks.

When an offline system is used where real-time feedback is needed, defects are often discovered too late, after dozens or hundreds of boards are already produced. On the other hand, forcing full inline inspection on complex, low-volume products can oversimplify inspection parameters and hide critical defects. The mismatch quietly increases quality risk without being immediately visible.

Adding more inspection steps does not automatically improve quality if those steps are poorly placed or incorrectly used. Inspection systems consume time, floor space, and engineering attention, all of which must deliver measurable value.

When inline X-ray is used where sampling would be sufficient, engineers may drown in data without clear action. When offline X-ray is overused for routine checks, valuable engineering time is wasted on low-risk boards. Effective inspection is about controlling the process, not inspecting everything equally.

Inline X-ray systems are physically and logically integrated into the SMT production flow, typically positioned after reflow. PCB move automatically through the system on conveyors, with no manual handling required. Inspection programs are designed to match line speed, often prioritizing consistency and repeatability over maximum image detail.

Because the system operates continuously, inspection results are generated in real time and can be linked to production data. This makes inline X-ray part of the manufacturing process rather than a separate quality checkpoint.

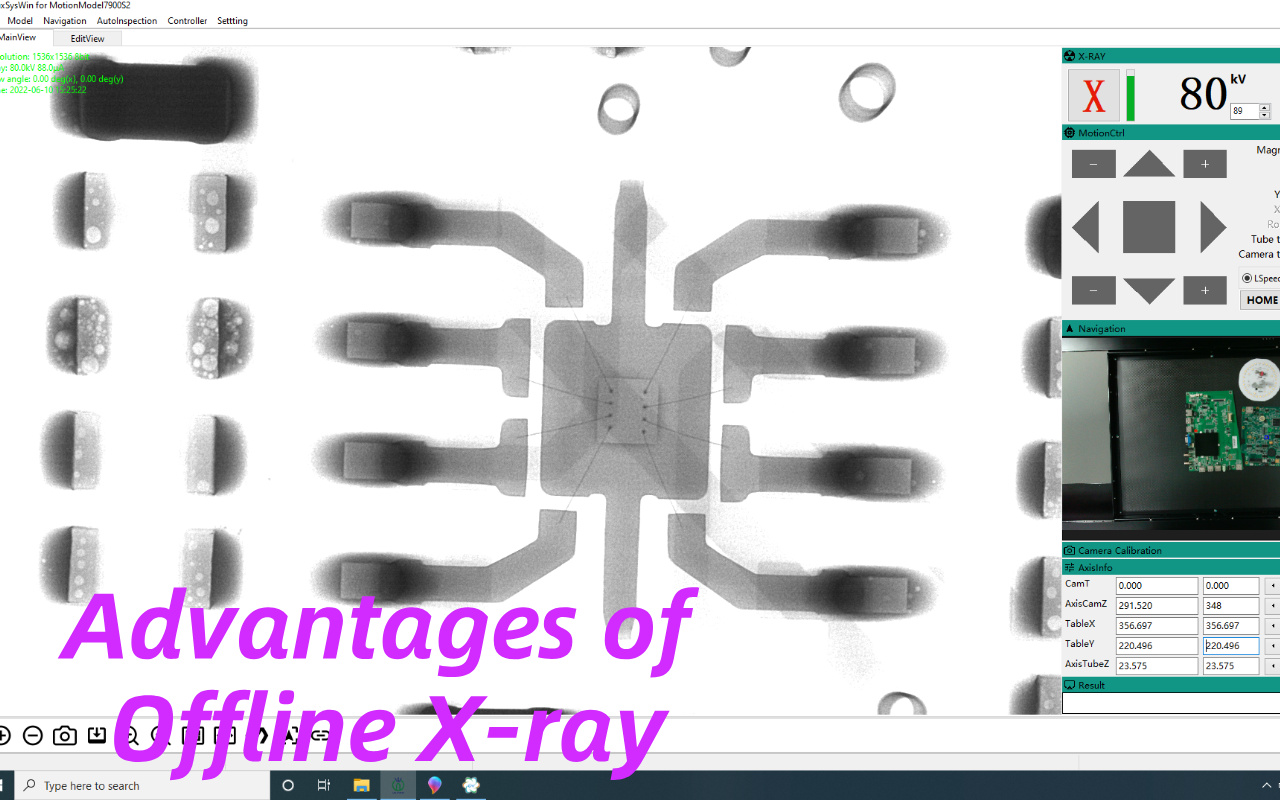

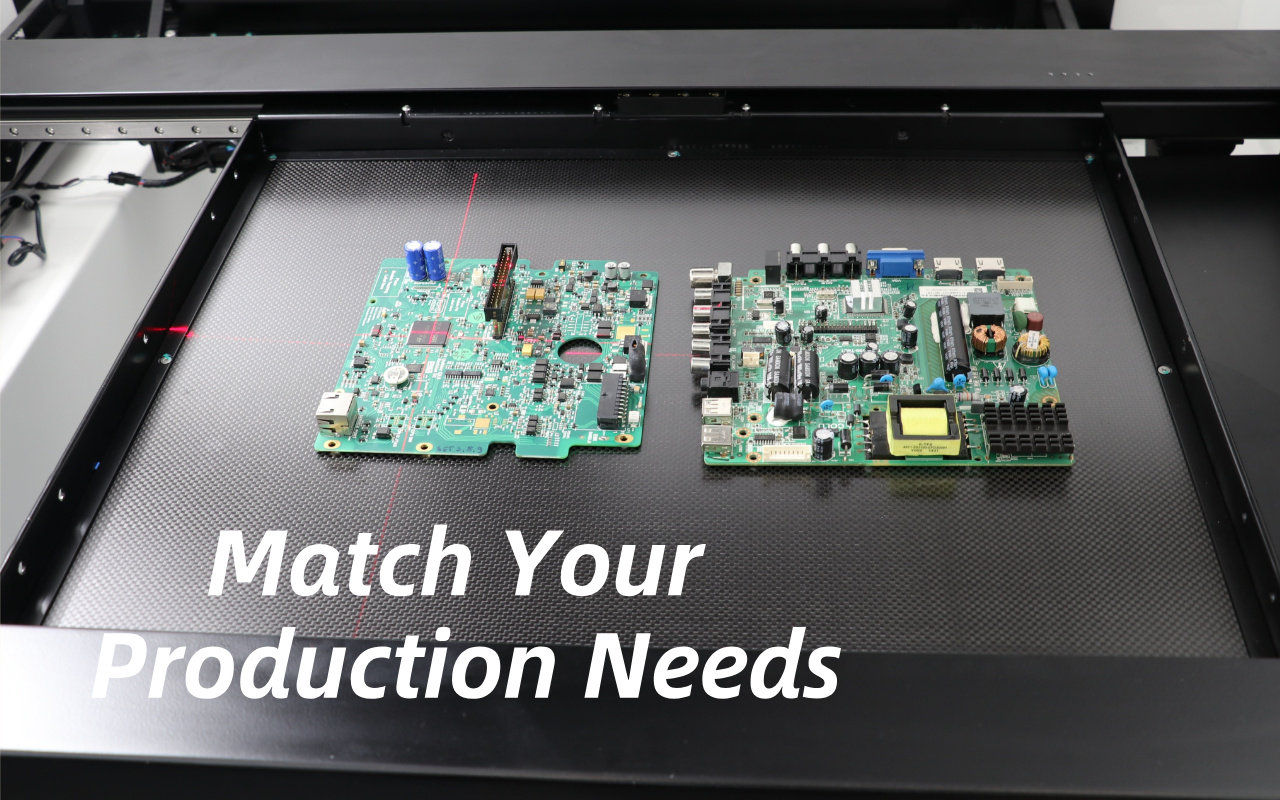

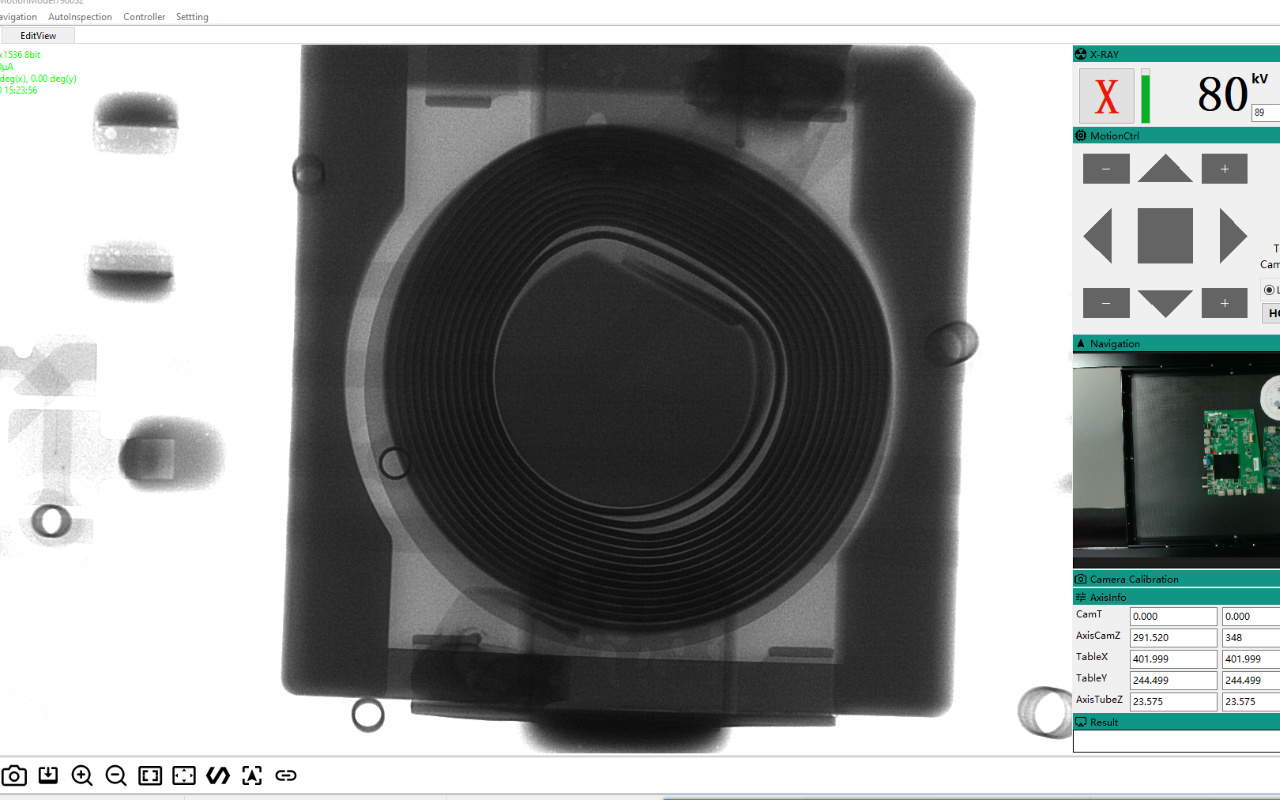

Offline X-ray systems function independently from the production line and rely on manual board loading and unloading. Operators or engineers decide which boards to inspect, how long to inspect them, and which features to analyze in detail.

This flexibility allows for deeper inspection, including angled views, multiple magnification levels, and longer analysis time per joint. Offline systems are commonly used for sampling, troubleshooting, and engineering validation. They act as an analytical tool rather than a throughput-driven inspection gate.

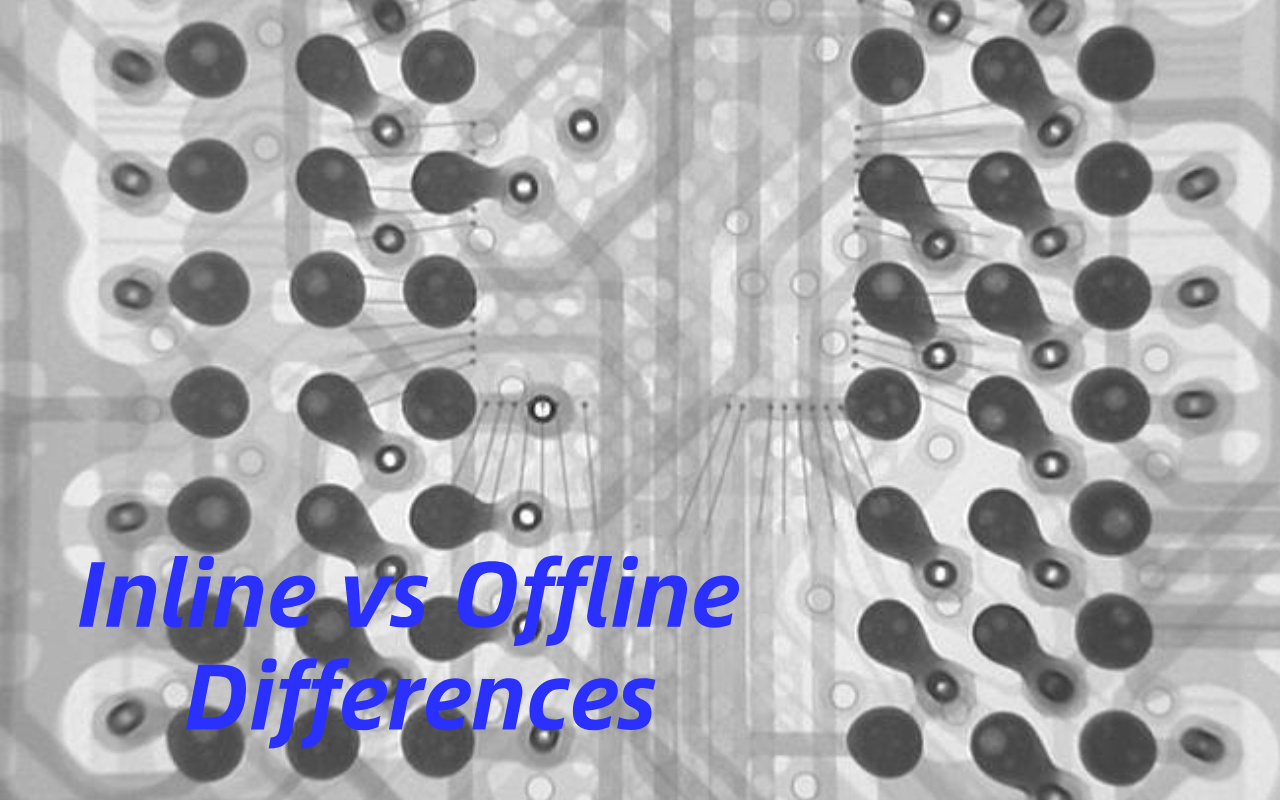

The most obvious difference between inline and offline X-ray is inspection speed. Inline systems are optimized to inspect every board quickly and consistently, while offline systems trade speed for detail. Automation levels also differ significantly, with inline systems requiring minimal operator involvement and offline systems relying heavily on skilled users.

Workflow-wise, inline inspection supports continuous production control, whereas offline inspection supports decision-making and root cause analysis. These distinctions directly influence how each system should be deployed in a factory.

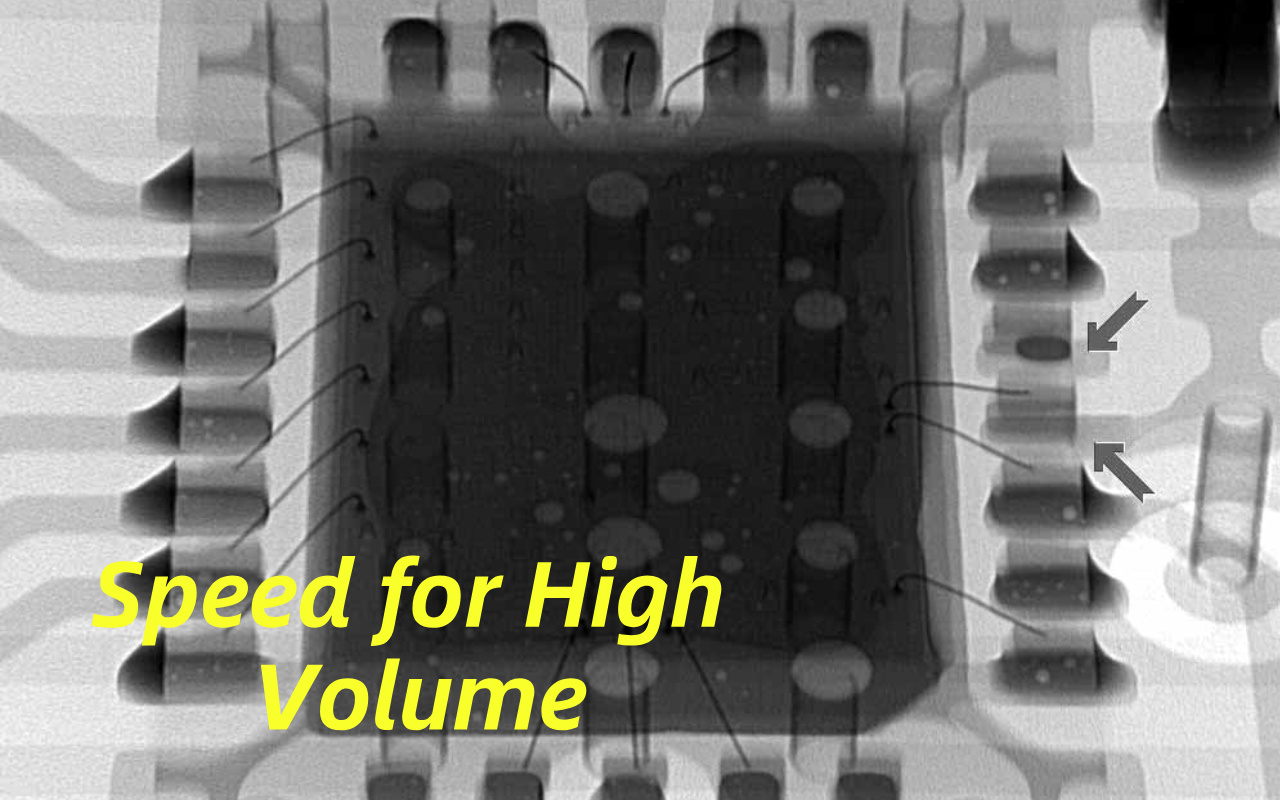

Inline X-ray inspection allows factories to maintain high output without sacrificing inspection coverage. Because boards are inspected automatically as they move through the line, there is no need to stop production or divert boards for manual handling.

This is especially important in high-volume environments where even short delays can disrupt delivery schedules. Inline inspection ensures that quality control keeps pace with production rather than competing with it. For many mass-production lines, this capability alone justifies the investment.

One of the strongest advantages of inline X-ray is the speed at which defects are detected and reported. Issues such as excessive voiding, solder bridging under components, or missing solder can be identified within minutes of occurrence.

This enables process engineers to react quickly by adjusting printing, placement, or reflow parameters. Early detection prevents defect propagation across large batches. Over time, this real-time feedback significantly stabilizes the entire SMT process.

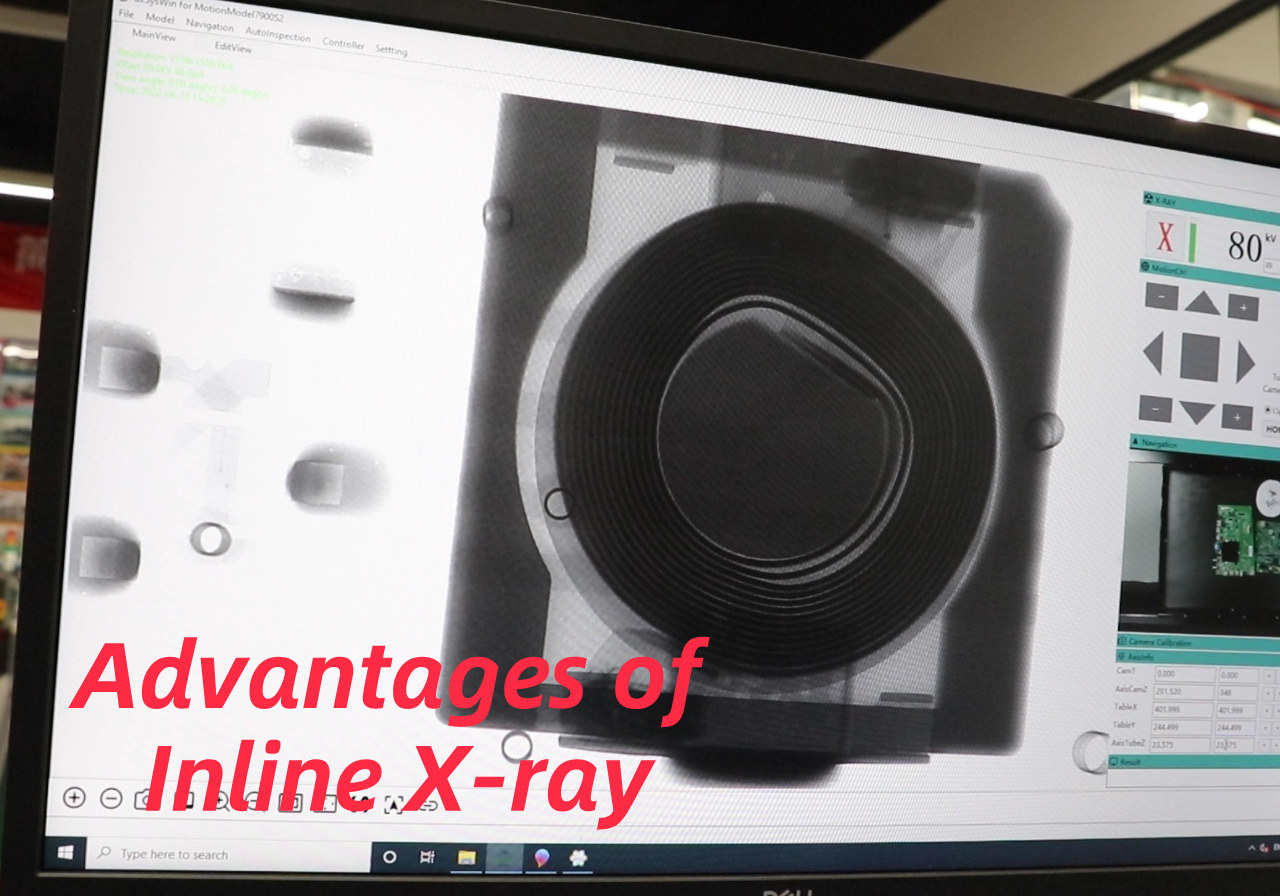

Inline X-ray systems are designed to communicate with other automated equipment on the line. Inspection data can be linked with printer, mounter, or reflow information to identify process trends. This supports statistical process control and long-term yield improvement.

When properly integrated, inline X-ray becomes part of a closed-loop quality system rather than a standalone checker. The result is a production line that not only detects defects but actively works to prevent them.

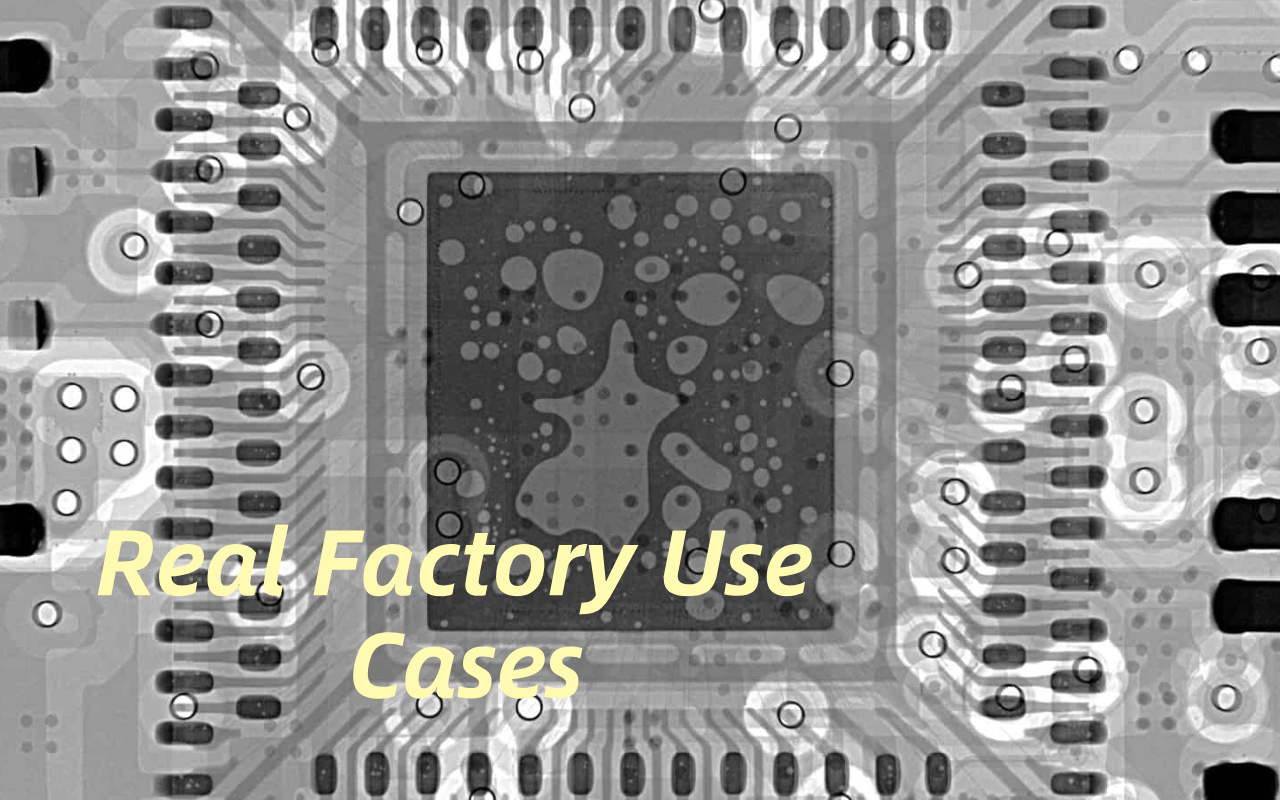

Offline X-ray systems allow operators to spend more time on each inspection target, which directly translates into higher image clarity and more inspection angles. Engineers can zoom in on individual solder joints, rotate views, and inspect complex structures layer by layer.

This level of detail is especially valuable when analyzing BGA voids, head-in-pillow defects, or partial non-wetting that would be difficult to classify in a fast inline scan. Offline inspection supports deeper understanding, not just defect confirmation. For quality engineers, this depth often makes the difference between guessing and knowing.

Offline X-ray excels in environments where products change frequently or where engineering analysis is required.

It is commonly used for:

New product introduction (NPI)

Process validation

Failure analysis and root cause investigation

Because offline X-ray is separated from the main SMT line, it does not directly affect line speed or uptime. Boards are selected for inspection after production, which avoids introducing new bottlenecks. This makes offline systems easier to introduce into existing factories without reconfiguring conveyors or line layout.

For facilities with limited floor space or unstable production schedules, this separation reduces operational risk. The inspection process remains controlled without interfering with daily output.

While inline X-ray offers speed and automation, it can become a bottleneck if not properly matched to line capacity. If inspection time per board exceeds the line takt time, queues will form and disrupt production flow. Complex boards with multiple inspection points are especially prone to this issue.

In some cases, engineers reduce inspection depth to maintain speed, which compromises defect detection. Without careful planning, inline inspection can unintentionally trade quality for throughput.

Offline X-ray inspection does not provide immediate feedback to the production line. By the time defects are discovered, dozens or even hundreds of boards may already be completed. This delay increases rework volume and makes root cause analysis more difficult.

Process issues remain hidden longer, allowing defects to repeat. Offline inspection works best when defect frequency is low and production volumes are manageable.

Both inline and offline systems require investment beyond the machine itself. Inline systems often demand additional conveyor space and integration effort, while offline systems rely heavily on skilled operators. Training, programming, and data interpretation all add to long-term costs.

Factories must consider not only purchase price but also operational overhead. Ignoring these factors often leads to underutilized equipment.

Production volume is one of the most important factors when choosing between inline and offline X-ray. High-volume, stable production favors inline inspection due to its speed and automation. Low-volume or frequently changing products benefit more from offline flexibility.

High-mix lines often struggle to justify inline programming effort for every product. Matching inspection strategy to actual production reality prevents wasted resources.

Not all defects require the same inspection approach. If your main concern is void percentage control in mass-produced BGAs, inline X-ray provides fast and consistent monitoring. If you need detailed analysis of intermittent or complex failures, offline systems are more effective.

Understanding your dominant defect modes is critical. Inspection should target risk, not operate blindly.

Inline systems typically require higher upfront investment and physical integration into the line. Offline systems offer lower entry barriers and can be expanded gradually. However, future growth must be considered from the start.

A factory planning significant volume increases may quickly outgrow an offline-only strategy. Choosing with long-term scalability in mind avoids costly reinvestment.

In high-volume automotive production, inline X-ray inspection is often essential. Continuous monitoring ensures that solder joint quality remains stable across thousands of boards per shift. Real-time feedback allows rapid correction before defects reach the customer.

Inline inspection becomes part of the quality assurance backbone. In this environment, offline inspection alone is insufficient.

Medical electronics manufacturers often prioritize traceability and deep defect analysis over raw throughput. Offline X-ray allows engineers to inspect critical boards in detail and document results for compliance.

Sampling strategies are carefully planned rather than fully automated. This approach balances inspection depth with production flexibility. Inline inspection may still be added later as volume grows.

Many factories ultimately adopt a hybrid approach combining inline and offline X-ray. Inline systems handle routine production monitoring, while offline systems support failure analysis and engineering investigations.

This division of labor maximizes inspection efficiency and knowledge depth. Hybrid strategies also reduce pressure on any single system. For growing factories, this approach offers the best long-term balance.

Inline X-ray supports speed, automation, and real-time control

Offline X-ray offers flexibility, resolution, and analytical depth

The right choice depends on volume, product mix, and quality risk

Hybrid strategies often deliver the best long-term balance

Yes. Many factories use inline inspection for production monitoring and offline systems for deeper analysis and troubleshooting.

3D inspection enhances defect detection in both configurations, but inspection time and data handling requirements should be considered carefully.

Inline systems require tighter uptime management, while offline systems offer more flexibility in scheduling maintenance.

Offline inspection can meet compliance needs when inspection plans and sampling strategies are properly defined.

ROI should consider not only equipment cost, but also labor savings, defect reduction, rework avoidance, and production efficiency.