RS-1R

JUKI

| Availability: | |

|---|---|

| Quantity: | |

| JUKI RS-1R Pick-and-Place Machine

The JUKI RS-1R sits right in the middle of SMT lines, doing the main job of putting surface-mount parts where they belong on circuit boards. It runs at a solid 47,000 CPH optimum, with accuracy at ±35µm, and takes boards from 50×50mm up to 650×370mm or larger with double clamping. The Takumi head switches tasks smoothly, placing everything from 0201 metric chips to 74mm square or 150×50mm pieces. Feeders go up to 112, so changeovers stay quick. It works fine alongside printers, reflow ovens, and inspection machines. I.C.T sets up complete lines around it, making sure the whole process flows without big headaches. Factories use it for LED boards, automotive electronics, and everyday PCBs.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

The RS-1R and RS-1XL form a practical pair of modular mounters for everyday SMT work. The RS-1R reaches 47,000 CPH optimum and holds placement accuracy at ±35µm (Cpk ≥1). It handles boards from 50×50 mm up to 650×370 mm in single clamping or 1,200×370 mm with double clamping. The RS-1XL extends board width to 650×560 mm, which suits larger panels such as LED assemblies. Both models use the Takumi head to place parts from 0201 metric (0.25×0.125 mm) to 74 mm square or 150×50 mm long. They support up to 112 feeders for fast setup changes. Compact dimensions help fit them into existing lines. Vision cameras (10/27/54 mm views) and force control options keep placement precise and gentle. These machines work well in mixed production where board sizes vary and speed must stay reliable.

RX-7R / RX-8 Series Features

The RX-7R and RX-8 focus on high output in small spaces. The RX-7R delivers 75,000 CPH with parallel heads and places tiny 03015 chips up to 25 mm square on boards as large as 510×450 mm single lane. The RX-8 pushes to 100,000 CPH optimum using the new P20 head, ideal for dense small-component work such as mobile devices or LED edge lighting. Both keep a narrow 998 mm width, giving the highest placement rate per square meter in their class. They include coaxial lighting for clear vision, low-impact placement to avoid board damage, and real-time monitoring to cut downtime. Dual-lane support and seamless data sharing with other equipment improve overall line efficiency. These models suit factories that need maximum throughput without expanding floor space.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T assembles dependable PCBA assembly lines centered on the JUKI SMT equipment for consistent daily performance. Vacuum loaders introduce clean boards from the start. Automatic printers apply paste with exact control. The mounter places every component firmly and true. Multi-zone reflow ovens bond solder evenly and strong. AOI systems inspect closely to catch any flaw early. Conveyors maintain smooth, uninterrupted flow. Yield rises steadily while costs fall away. No unnecessary pauses or rework appear. Lines manage demanding work—automotive power units, LED assemblies, and beyond. Completed boards emerge prepared for final use. I.C.T supports the entire chain from beginning to end.

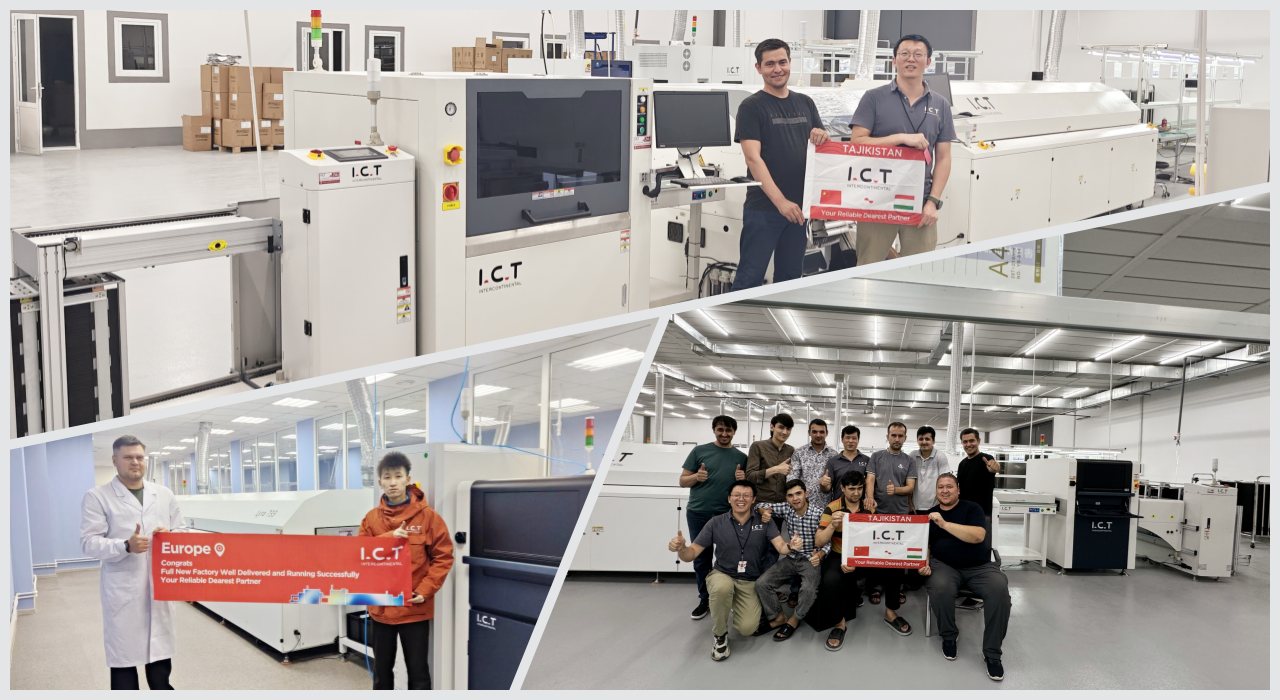

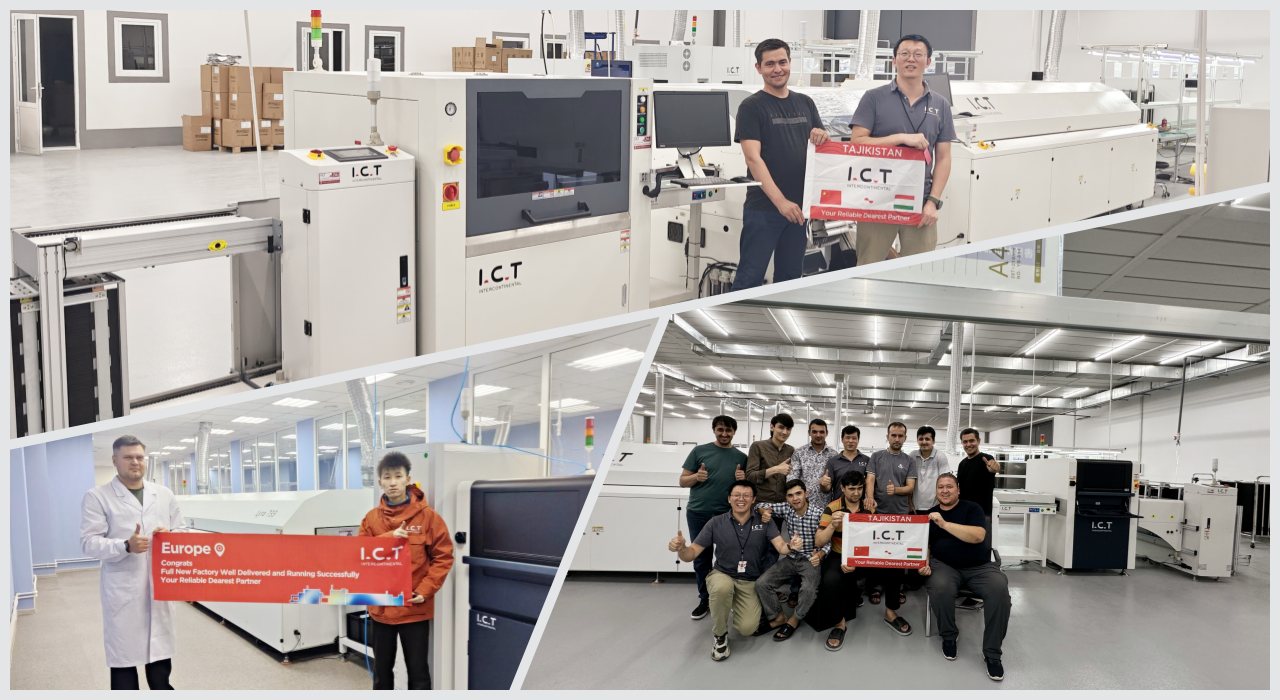

| Customer Success Video

The video shows a customer explaining their full SMT and DIP lines used for automotive power supply production. They point out the vacuum loader starting things clean, cleaner wiping boards, printer applying paste, then the JUKI RS-1R mounting components quickly and precisely. Conveyors move boards to reflow, cooling buffer, AOI inspection, and unloaders. The DIP section covers wave soldering, flipping, ICT testing, and connections. Footage keeps it straightforward—machines run without fuss, boards travel smooth, placement looks exact. The customer says defects stay low, production pace holds steady, and quality meets automotive standards. Downtime remains small in their everyday operation.

| Service and Training Support

I.C.T provides full support for complete factory lines featuring JUKI RS-1R and other equipment. Engineers come on site to install machines and get lines running. They train operators on daily use, program setup, maintenance, and quick fixes. Remote tools let them solve problems fast from anywhere. Regular visits keep everything at top performance. Teams help adjust lines for new products or higher output without long breaks. With offices worldwide, response times stay short. This ongoing help turns equipment into tools factories can count on for years of steady work.

| Customer Feedback

Customers often say I.C.T engineers show up prepared and fix issues right away. They praise the JUKI RS-1R for running fast and reliable through long shifts. Packing arrives secure—machines show up in good shape after shipping. Questions get answered quickly, keeping production from stopping. Many mention the full line performs better than expected, with fewer defects and smoother flow. Trust comes from solid equipment and people who follow through. Factories appreciate the consistent support that makes daily work easier.

| Certifications and Standards

The JUKI RS-1R carries CE marking for safety in Europe, RoHS for green materials, and ISO9001 for quality control. Multiple patents cover placement heads, vision tech, and other features. These certifications show the machine meets international rules for safe, clean, and consistent operation. Plants install it knowing standards stay met. They prove a focus on building durable equipment that performs well under real conditions.

| About I.C.T Company and Factory

I.C.T runs its own research and development to improve SMT equipment over time. Production takes place in a large factory with strict checks at every step. The company has grown fast since 2012, with many employees and eight branch offices. It serves over 1600 customers in more than 72 countries. Quality systems track every process so machines hold up in daily use. I.C.T offers complete factory solutions—from planning full lines to later upgrades—helping electronics manufacturers keep operations steady and efficient around the world.

| JUKI RS-1R Pick-and-Place Machine

The JUKI RS-1R sits right in the middle of SMT lines, doing the main job of putting surface-mount parts where they belong on circuit boards. It runs at a solid 47,000 CPH optimum, with accuracy at ±35µm, and takes boards from 50×50mm up to 650×370mm or larger with double clamping. The Takumi head switches tasks smoothly, placing everything from 0201 metric chips to 74mm square or 150×50mm pieces. Feeders go up to 112, so changeovers stay quick. It works fine alongside printers, reflow ovens, and inspection machines. I.C.T sets up complete lines around it, making sure the whole process flows without big headaches. Factories use it for LED boards, automotive electronics, and everyday PCBs.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

The RS-1R and RS-1XL form a practical pair of modular mounters for everyday SMT work. The RS-1R reaches 47,000 CPH optimum and holds placement accuracy at ±35µm (Cpk ≥1). It handles boards from 50×50 mm up to 650×370 mm in single clamping or 1,200×370 mm with double clamping. The RS-1XL extends board width to 650×560 mm, which suits larger panels such as LED assemblies. Both models use the Takumi head to place parts from 0201 metric (0.25×0.125 mm) to 74 mm square or 150×50 mm long. They support up to 112 feeders for fast setup changes. Compact dimensions help fit them into existing lines. Vision cameras (10/27/54 mm views) and force control options keep placement precise and gentle. These machines work well in mixed production where board sizes vary and speed must stay reliable.

RX-7R / RX-8 Series Features

The RX-7R and RX-8 focus on high output in small spaces. The RX-7R delivers 75,000 CPH with parallel heads and places tiny 03015 chips up to 25 mm square on boards as large as 510×450 mm single lane. The RX-8 pushes to 100,000 CPH optimum using the new P20 head, ideal for dense small-component work such as mobile devices or LED edge lighting. Both keep a narrow 998 mm width, giving the highest placement rate per square meter in their class. They include coaxial lighting for clear vision, low-impact placement to avoid board damage, and real-time monitoring to cut downtime. Dual-lane support and seamless data sharing with other equipment improve overall line efficiency. These models suit factories that need maximum throughput without expanding floor space.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T assembles dependable PCBA assembly lines centered on the JUKI SMT equipment for consistent daily performance. Vacuum loaders introduce clean boards from the start. Automatic printers apply paste with exact control. The mounter places every component firmly and true. Multi-zone reflow ovens bond solder evenly and strong. AOI systems inspect closely to catch any flaw early. Conveyors maintain smooth, uninterrupted flow. Yield rises steadily while costs fall away. No unnecessary pauses or rework appear. Lines manage demanding work—automotive power units, LED assemblies, and beyond. Completed boards emerge prepared for final use. I.C.T supports the entire chain from beginning to end.

| Customer Success Video

The video shows a customer explaining their full SMT and DIP lines used for automotive power supply production. They point out the vacuum loader starting things clean, cleaner wiping boards, printer applying paste, then the JUKI RS-1R mounting components quickly and precisely. Conveyors move boards to reflow, cooling buffer, AOI inspection, and unloaders. The DIP section covers wave soldering, flipping, ICT testing, and connections. Footage keeps it straightforward—machines run without fuss, boards travel smooth, placement looks exact. The customer says defects stay low, production pace holds steady, and quality meets automotive standards. Downtime remains small in their everyday operation.

| Service and Training Support

I.C.T provides full support for complete factory lines featuring JUKI RS-1R and other equipment. Engineers come on site to install machines and get lines running. They train operators on daily use, program setup, maintenance, and quick fixes. Remote tools let them solve problems fast from anywhere. Regular visits keep everything at top performance. Teams help adjust lines for new products or higher output without long breaks. With offices worldwide, response times stay short. This ongoing help turns equipment into tools factories can count on for years of steady work.

| Customer Feedback

Customers often say I.C.T engineers show up prepared and fix issues right away. They praise the JUKI RS-1R for running fast and reliable through long shifts. Packing arrives secure—machines show up in good shape after shipping. Questions get answered quickly, keeping production from stopping. Many mention the full line performs better than expected, with fewer defects and smoother flow. Trust comes from solid equipment and people who follow through. Factories appreciate the consistent support that makes daily work easier.

| Certifications and Standards

The JUKI RS-1R carries CE marking for safety in Europe, RoHS for green materials, and ISO9001 for quality control. Multiple patents cover placement heads, vision tech, and other features. These certifications show the machine meets international rules for safe, clean, and consistent operation. Plants install it knowing standards stay met. They prove a focus on building durable equipment that performs well under real conditions.

| About I.C.T Company and Factory

I.C.T runs its own research and development to improve SMT equipment over time. Production takes place in a large factory with strict checks at every step. The company has grown fast since 2012, with many employees and eight branch offices. It serves over 1600 customers in more than 72 countries. Quality systems track every process so machines hold up in daily use. I.C.T offers complete factory solutions—from planning full lines to later upgrades—helping electronics manufacturers keep operations steady and efficient around the world.