RS-1R

JUKI

| Availability: | |

|---|---|

| Quantity: | |

| JUKI Placement Machines

The JUKI placement machines handle the main job in SMT lines—mounting surface parts on circuit boards fast and straight. RS models like the RS-1R give solid speed and take different board sizes without complaint. RX models push harder in small spaces, hitting high numbers when room is tight. They place tiny chips, ICs, and bigger pieces with good accuracy. The machines fit printers, ovens, and inspection gear to make whole lines run smooth. I.C.T builds complete setups around them, from planning to daily running. Factories use these for car electronics, LED lights, and regular PCBs. The point is simple: get boards done right and keep production going day after day.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

The RS-1R and RS-1XL make practical all-around mounters for most SMT jobs. The RS-1R hits 47,000 CPH optimum with ±35µm accuracy and takes boards up to 650×370 mm single clamp or 1,200×370 mm double. The RS-1XL stretches board width to 650×560 mm for bigger work like LED panels. Both run the Takumi head that switches between small 0201 chips and parts up to 74 mm square or 150×50 mm long. Feeders go to 112 max so changeovers stay quick. The build stays compact for easy line fit. Vision cameras spot trouble early and force control keeps delicate parts safe. These suit shops that mix jobs and need steady speed without big changes.

RX-7R / RX-8 Series Features

The RX-7R and RX-8 aim at high output when floor space costs money. The RX-7R runs 75,000 CPH with parallel heads and places 03015 tiny chips up to 25 mm square on 510×450 mm boards. The RX-8 reaches 100,000 CPH with the P20 head for crowded small-part runs. Both sit only 998 mm wide, giving top placement per square meter. They use coaxial lighting for clear views, low-impact touch to avoid damage, and monitoring to cut idle time. Dual lanes and data sharing with other machines keep the whole line moving. These fit high-volume work on phones, lights, or auto parts where every second and every foot of space counts.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T assembles dependable PCBA assembly lines centered on the JUKI SMT equipment for consistent daily performance. Vacuum loaders introduce clean boards from the start. Automatic printers apply paste with exact control. The mounter places every component firmly and true. Multi-zone reflow ovens bond solder evenly and strong. AOI systems inspect closely to catch any flaw early. Conveyors maintain smooth, uninterrupted flow. Yield rises steadily while costs fall away. No unnecessary pauses or rework appear. Lines manage demanding work—automotive power units, LED assemblies, and beyond. Completed boards emerge prepared for final use. I.C.T supports the entire chain from beginning to end.

| Customer Success Video

In the video a customer walks through their full SMT and DIP lines making automotive power supplies. They show the loader bringing clean boards, cleaner wiping them, printer laying paste, then the JUKI placement machines putting parts down fast and true. Conveyors carry boards to reflow, cooling buffer, AOI check, and unloaders. The DIP side has wave solder flowing, flipper turning boards, ICT testing connections. The footage stays plain—machines do their job, boards move smooth, placement looks sharp. The customer says errors stay low, speed holds steady, and quality fits car standards. Downtime stays small in their regular shop days.

| Service and Training Support

I.C.T gives full backing for whole factory lines that use JUKI placement machines. Engineers go to the plant for setup and startup work. They train folks on daily checks, making programs, keeping machines clean, and fixing small troubles. Remote help clears up problems quick from far away. Regular visits make sure everything runs right for years. Teams adjust lines for new work or more output without long waits. Offices sit around the world so help comes fast. This steady support turns machines into tools shops can trust and keeps production even.

| Customer Feedback

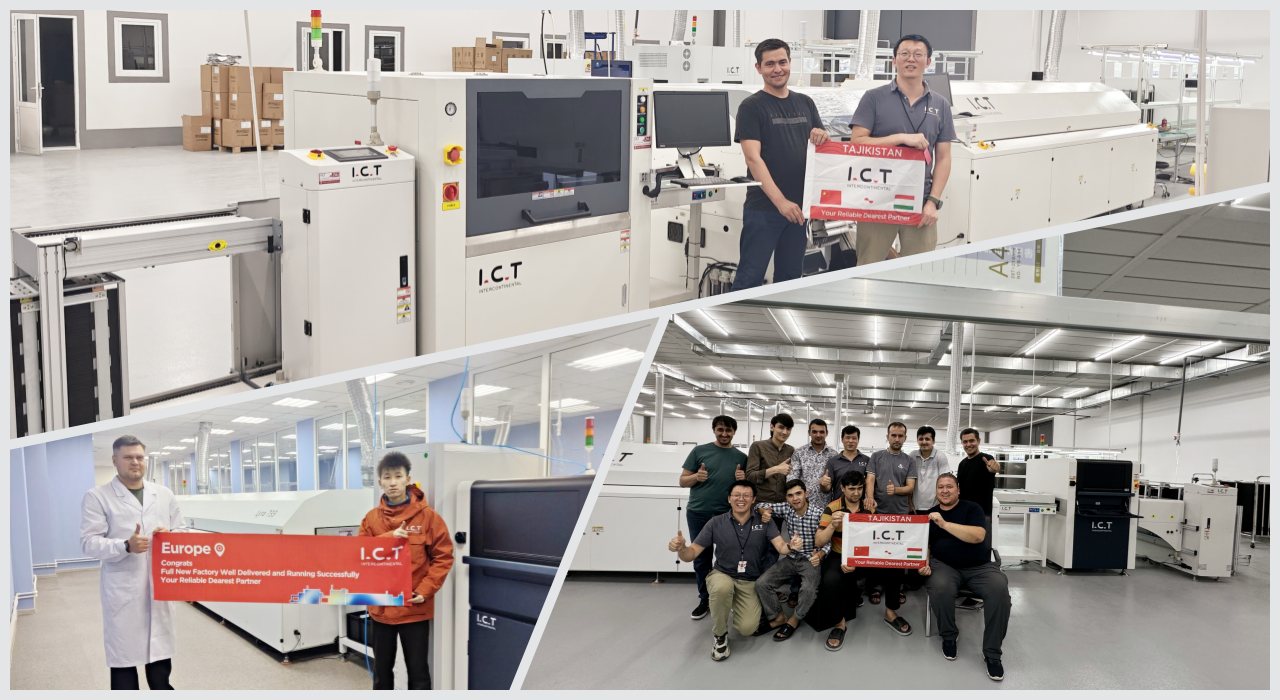

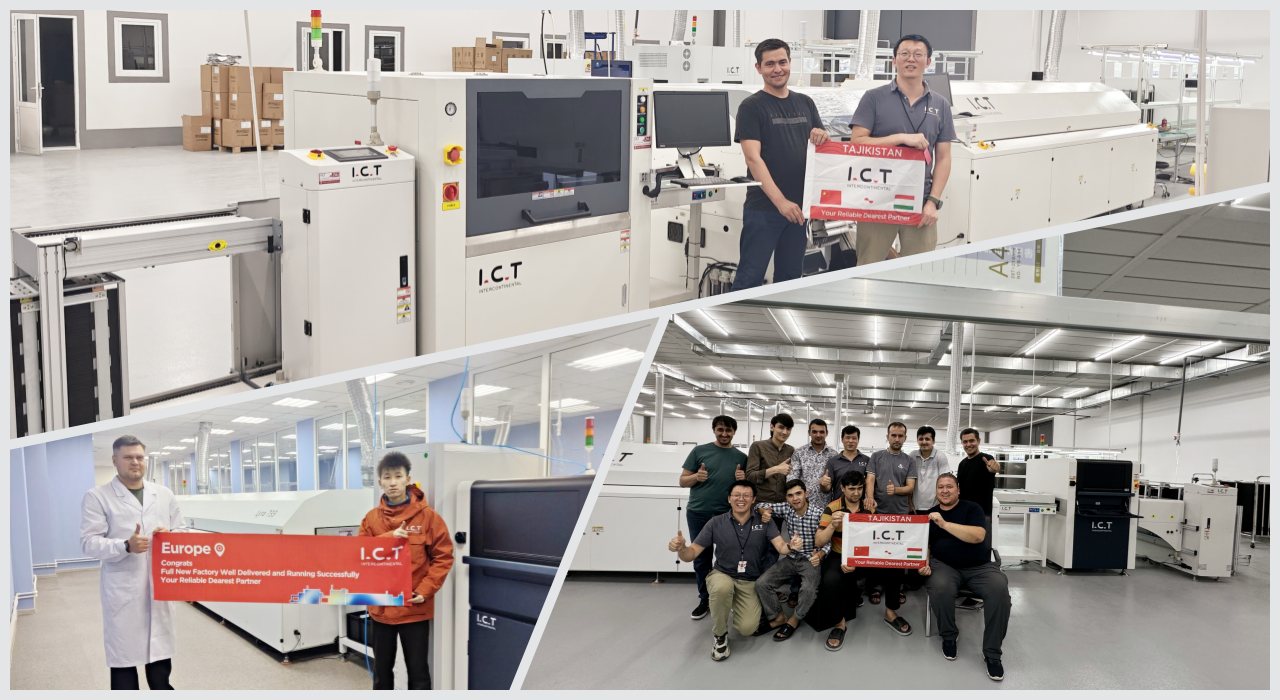

Customers talk plain about I.C.T engineers who show up ready and fix things fast. They like how the JUKI placement machines run strong shift after shift with good speed and few mistakes. Packing holds up—machines arrive safe after long trips. Answers come quick when questions pop up, so lines don’t sit idle. Many say the full setup works better than they figured, with cleaner boards and less trouble. Trust grows from solid gear and people who keep their word. Shops count on I.C.T to make the job easier.

| Certifications and Standards

The JUKI placement machines carry CE for safety rules in Europe, RoHS to keep out bad materials, and ISO9001 for steady quality control. Several patents cover the heads, vision, and other smart parts. These papers show the machines meet clear world standards for safe, clean, and reliable work. Factories put them in knowing rules stay followed. They prove plain focus on making equipment that lasts and does the job right every time.

| About I.C.T Company and Factory

I.C.T keeps its own research team busy improving SMT gear year by year. The factory runs large with careful checks from start to finish on every machine. Since 2012 the company has grown quick, with many workers and eight branch offices. It serves over 1600 customers in more than 72 countries. Strict quality steps track all work so machines hold up under hard daily use. I.C.T gives complete factory help—from first plans to later changes—helping electronics shops stay steady and grow without big worries.

| JUKI Placement Machines

The JUKI placement machines handle the main job in SMT lines—mounting surface parts on circuit boards fast and straight. RS models like the RS-1R give solid speed and take different board sizes without complaint. RX models push harder in small spaces, hitting high numbers when room is tight. They place tiny chips, ICs, and bigger pieces with good accuracy. The machines fit printers, ovens, and inspection gear to make whole lines run smooth. I.C.T builds complete setups around them, from planning to daily running. Factories use these for car electronics, LED lights, and regular PCBs. The point is simple: get boards done right and keep production going day after day.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

The RS-1R and RS-1XL make practical all-around mounters for most SMT jobs. The RS-1R hits 47,000 CPH optimum with ±35µm accuracy and takes boards up to 650×370 mm single clamp or 1,200×370 mm double. The RS-1XL stretches board width to 650×560 mm for bigger work like LED panels. Both run the Takumi head that switches between small 0201 chips and parts up to 74 mm square or 150×50 mm long. Feeders go to 112 max so changeovers stay quick. The build stays compact for easy line fit. Vision cameras spot trouble early and force control keeps delicate parts safe. These suit shops that mix jobs and need steady speed without big changes.

RX-7R / RX-8 Series Features

The RX-7R and RX-8 aim at high output when floor space costs money. The RX-7R runs 75,000 CPH with parallel heads and places 03015 tiny chips up to 25 mm square on 510×450 mm boards. The RX-8 reaches 100,000 CPH with the P20 head for crowded small-part runs. Both sit only 998 mm wide, giving top placement per square meter. They use coaxial lighting for clear views, low-impact touch to avoid damage, and monitoring to cut idle time. Dual lanes and data sharing with other machines keep the whole line moving. These fit high-volume work on phones, lights, or auto parts where every second and every foot of space counts.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T assembles dependable PCBA assembly lines centered on the JUKI SMT equipment for consistent daily performance. Vacuum loaders introduce clean boards from the start. Automatic printers apply paste with exact control. The mounter places every component firmly and true. Multi-zone reflow ovens bond solder evenly and strong. AOI systems inspect closely to catch any flaw early. Conveyors maintain smooth, uninterrupted flow. Yield rises steadily while costs fall away. No unnecessary pauses or rework appear. Lines manage demanding work—automotive power units, LED assemblies, and beyond. Completed boards emerge prepared for final use. I.C.T supports the entire chain from beginning to end.

| Customer Success Video

In the video a customer walks through their full SMT and DIP lines making automotive power supplies. They show the loader bringing clean boards, cleaner wiping them, printer laying paste, then the JUKI placement machines putting parts down fast and true. Conveyors carry boards to reflow, cooling buffer, AOI check, and unloaders. The DIP side has wave solder flowing, flipper turning boards, ICT testing connections. The footage stays plain—machines do their job, boards move smooth, placement looks sharp. The customer says errors stay low, speed holds steady, and quality fits car standards. Downtime stays small in their regular shop days.

| Service and Training Support

I.C.T gives full backing for whole factory lines that use JUKI placement machines. Engineers go to the plant for setup and startup work. They train folks on daily checks, making programs, keeping machines clean, and fixing small troubles. Remote help clears up problems quick from far away. Regular visits make sure everything runs right for years. Teams adjust lines for new work or more output without long waits. Offices sit around the world so help comes fast. This steady support turns machines into tools shops can trust and keeps production even.

| Customer Feedback

Customers talk plain about I.C.T engineers who show up ready and fix things fast. They like how the JUKI placement machines run strong shift after shift with good speed and few mistakes. Packing holds up—machines arrive safe after long trips. Answers come quick when questions pop up, so lines don’t sit idle. Many say the full setup works better than they figured, with cleaner boards and less trouble. Trust grows from solid gear and people who keep their word. Shops count on I.C.T to make the job easier.

| Certifications and Standards

The JUKI placement machines carry CE for safety rules in Europe, RoHS to keep out bad materials, and ISO9001 for steady quality control. Several patents cover the heads, vision, and other smart parts. These papers show the machines meet clear world standards for safe, clean, and reliable work. Factories put them in knowing rules stay followed. They prove plain focus on making equipment that lasts and does the job right every time.

| About I.C.T Company and Factory

I.C.T keeps its own research team busy improving SMT gear year by year. The factory runs large with careful checks from start to finish on every machine. Since 2012 the company has grown quick, with many workers and eight branch offices. It serves over 1600 customers in more than 72 countries. Strict quality steps track all work so machines hold up under hard daily use. I.C.T gives complete factory help—from first plans to later changes—helping electronics shops stay steady and grow without big worries.