RS-1R

JUKI

| Availability: | |

|---|---|

| Quantity: | |

| High-Performance LED Assembly Solution

In the world of LED manufacturing, reliability and efficiency matter most. The SMT pick and place machine for LED from Juki delivers both in elegant balance. It positions surface-mount components on boards with remarkable accuracy and grace. Modular design allows easy expansion as needs grow. Real-time vision systems watch every detail. Programming flows simply, saving valuable time. The compact frame blends seamlessly into any line. I.C.T provides guidance from initial planning through daily production. Lines run smoothly, yields rise steadily, and LED boards emerge ready for demanding applications. This series stands as a refined choice for quality-driven factories.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

Graceful versatility defines these models. The RS-1R achieves 47,000 CPH while maintaining ±35µm precision. It accommodates boards up to 650×370mm, extending wider on the RS-1XL to 650×560mm for large LED panels. The Takumi head adapts intelligently during operation, managing diverse shapes and mixed runs. Up to 112 feeders enable swift changeovers. Vision systems detect issues instantly; gentle force control safeguards delicate substrates. These machines integrate beautifully in flexible lines, pairing well with high-speed units. Production shifts flow without interruption, delivering consistent excellence for varied LED applications.

RX-7R / RX-8 Series Features

Pure velocity shines here in refined form. The RX-7R attains 75,000 CPH; the RX-8 rises to 100,000 CPH through the innovative P20 head. Both maintain a slender 998mm width, leading in output per square foot. They handle ultra-small 03015 chips flawlessly. Parallel heads operate in perfect harmony. Coaxial lighting reveals clear images for superior vision. Soft-impact placement protects fragile components. Machines communicate seamlessly, sharing data and maintaining supply. Ideal for high-volume fine-pitch work in LED drivers and similar products, they offer unmatched speed within limited space.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T creates lasting, high-quality SMT production lines with thoughtful design. PCB loader delivers boards perfectly clean. Automatic printer applies paste in precise, even layers. The SMT pick and place machine for LED positions every component exactly. Multi-zone reflow ovens secure strong solder joints. Advanced AOI detects any imperfection early. Conveyors connect each station tightly. Buffers maintain steady rhythm. Yield improves dramatically while costs decline. No fragile links exist. Built strong for automotive power modules and LED production, finished boards arrive ready for real-world demands. Full backing stands behind every system.

| Customer Success Video

A manufacturer of automotive power supplies shares their story through clear video footage. Complete SMT and DIP lines operate in harmonious flow. Boards enter spotless via vacuum loader. Paste spreads flawlessly at the printer. The SMT pick and place machine for LED fills positions rapidly and true. Reflow ovens solidify connections; cooling stations and buffers preserve pace. AOI examines every detail carefully. On the DIP side, wave soldering handles through-hole components cleanly, flippers reorient boards, ICT verifies performance. The customer speaks with satisfaction: seamless connection throughout, minimal stops, consistently high quality. Video captures the entire journey from raw board to finished product built for rigorous duty.

| Service and Training Support

I.C.T commits fully to customer success. Experienced engineers arrive onsite, install the SMT pick and place machine for LED, and verify every function. Training unfolds patiently—operators master programming, routine care, and efficient troubleshooting. Remote connections resolve issues swiftly. Comprehensive maintenance programs preserve peak performance across years. We analyze complete lines and recommend refined improvements. Upgrades integrate smoothly. Worldwide offices ensure rapid response anywhere. Customers maintain full production rhythm with rare interruptions. Partnership builds naturally from the very beginning.

| Customer Feedback

Customers express genuine appreciation. They commend our engineers for arriving prepared and resolving matters expertly. The SMT pick and place machine for LED earns admiration for reliable speed and minimal errors. Careful packaging ensures safe arrival across distances. Inquiries receive prompt, clear replies—often same day. Service maintains close connection despite geography. Lines operate longer with reduced issues. Production volumes increase noticeably. Overall, clients value the combination of superior equipment, skilled people, and responsive support that elevates daily performance. Trust deepens steadily through consistent excellence.

| Certifications and Standards

Each SMT pick and place machine for LED carries distinguished certifications. CE confirms compliance with strict European safety requirements. RoHS verifies absence of harmful substances. ISO9001 governs rigorous quality management from design to delivery. Numerous patents protect innovative head designs and vision technology. These credentials assure customers of machines that prioritize worker safety, environmental responsibility, and enduring performance. Global regulations are satisfied completely, providing purchase confidence without question.

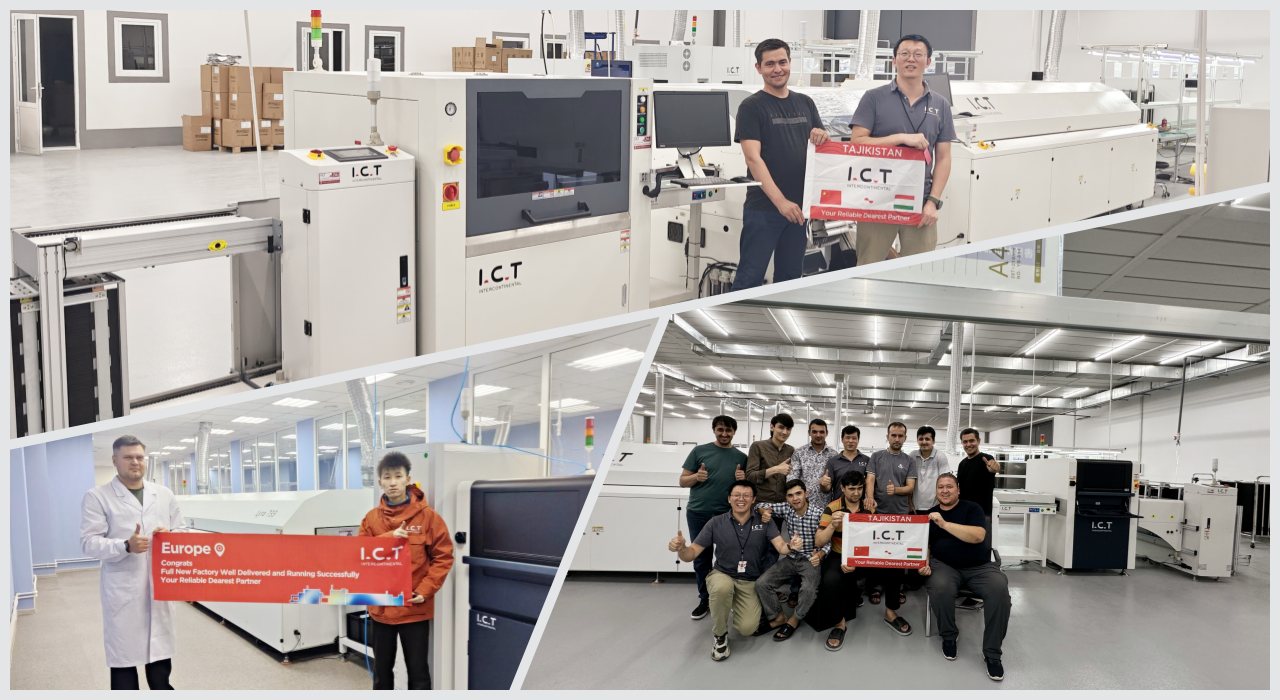

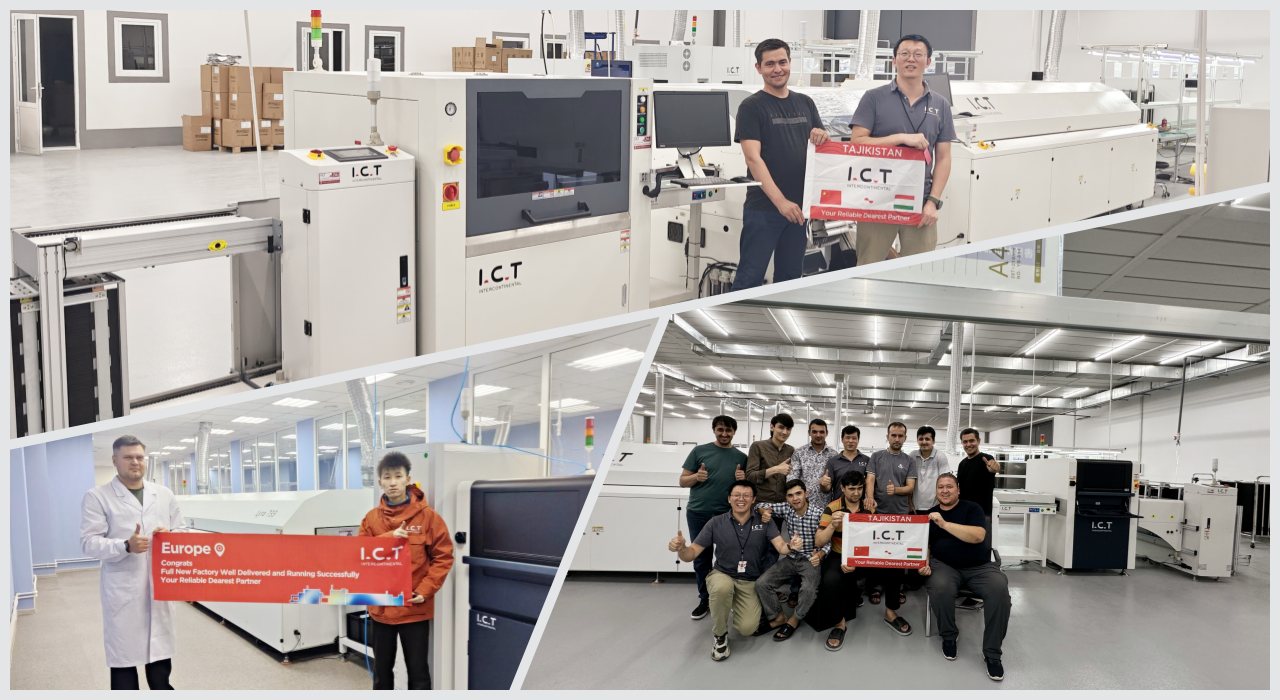

| About I.C.T Company and Factory

I.C.T maintains dedicated research teams that transform ideas into advanced solutions. Production occurs in spacious, modern facilities with meticulous testing at every phase. Employee numbers expand steadily. Branch offices multiply across nations. More than 1600 customers in 72 countries rely on our systems today. Rapid growth reflects committed effort and visible results. Comprehensive quality management oversees each component. The SMT pick and place machine for LED emerges fully prepared for intensive daily operation. We serve as a trusted global partner in electronics manufacturing.

| High-Performance LED Assembly Solution

In the world of LED manufacturing, reliability and efficiency matter most. The SMT pick and place machine for LED from Juki delivers both in elegant balance. It positions surface-mount components on boards with remarkable accuracy and grace. Modular design allows easy expansion as needs grow. Real-time vision systems watch every detail. Programming flows simply, saving valuable time. The compact frame blends seamlessly into any line. I.C.T provides guidance from initial planning through daily production. Lines run smoothly, yields rise steadily, and LED boards emerge ready for demanding applications. This series stands as a refined choice for quality-driven factories.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

Graceful versatility defines these models. The RS-1R achieves 47,000 CPH while maintaining ±35µm precision. It accommodates boards up to 650×370mm, extending wider on the RS-1XL to 650×560mm for large LED panels. The Takumi head adapts intelligently during operation, managing diverse shapes and mixed runs. Up to 112 feeders enable swift changeovers. Vision systems detect issues instantly; gentle force control safeguards delicate substrates. These machines integrate beautifully in flexible lines, pairing well with high-speed units. Production shifts flow without interruption, delivering consistent excellence for varied LED applications.

RX-7R / RX-8 Series Features

Pure velocity shines here in refined form. The RX-7R attains 75,000 CPH; the RX-8 rises to 100,000 CPH through the innovative P20 head. Both maintain a slender 998mm width, leading in output per square foot. They handle ultra-small 03015 chips flawlessly. Parallel heads operate in perfect harmony. Coaxial lighting reveals clear images for superior vision. Soft-impact placement protects fragile components. Machines communicate seamlessly, sharing data and maintaining supply. Ideal for high-volume fine-pitch work in LED drivers and similar products, they offer unmatched speed within limited space.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T creates lasting, high-quality SMT production lines with thoughtful design. PCB loader delivers boards perfectly clean. Automatic printer applies paste in precise, even layers. The SMT pick and place machine for LED positions every component exactly. Multi-zone reflow ovens secure strong solder joints. Advanced AOI detects any imperfection early. Conveyors connect each station tightly. Buffers maintain steady rhythm. Yield improves dramatically while costs decline. No fragile links exist. Built strong for automotive power modules and LED production, finished boards arrive ready for real-world demands. Full backing stands behind every system.

| Customer Success Video

A manufacturer of automotive power supplies shares their story through clear video footage. Complete SMT and DIP lines operate in harmonious flow. Boards enter spotless via vacuum loader. Paste spreads flawlessly at the printer. The SMT pick and place machine for LED fills positions rapidly and true. Reflow ovens solidify connections; cooling stations and buffers preserve pace. AOI examines every detail carefully. On the DIP side, wave soldering handles through-hole components cleanly, flippers reorient boards, ICT verifies performance. The customer speaks with satisfaction: seamless connection throughout, minimal stops, consistently high quality. Video captures the entire journey from raw board to finished product built for rigorous duty.

| Service and Training Support

I.C.T commits fully to customer success. Experienced engineers arrive onsite, install the SMT pick and place machine for LED, and verify every function. Training unfolds patiently—operators master programming, routine care, and efficient troubleshooting. Remote connections resolve issues swiftly. Comprehensive maintenance programs preserve peak performance across years. We analyze complete lines and recommend refined improvements. Upgrades integrate smoothly. Worldwide offices ensure rapid response anywhere. Customers maintain full production rhythm with rare interruptions. Partnership builds naturally from the very beginning.

| Customer Feedback

Customers express genuine appreciation. They commend our engineers for arriving prepared and resolving matters expertly. The SMT pick and place machine for LED earns admiration for reliable speed and minimal errors. Careful packaging ensures safe arrival across distances. Inquiries receive prompt, clear replies—often same day. Service maintains close connection despite geography. Lines operate longer with reduced issues. Production volumes increase noticeably. Overall, clients value the combination of superior equipment, skilled people, and responsive support that elevates daily performance. Trust deepens steadily through consistent excellence.

| Certifications and Standards

Each SMT pick and place machine for LED carries distinguished certifications. CE confirms compliance with strict European safety requirements. RoHS verifies absence of harmful substances. ISO9001 governs rigorous quality management from design to delivery. Numerous patents protect innovative head designs and vision technology. These credentials assure customers of machines that prioritize worker safety, environmental responsibility, and enduring performance. Global regulations are satisfied completely, providing purchase confidence without question.

| About I.C.T Company and Factory

I.C.T maintains dedicated research teams that transform ideas into advanced solutions. Production occurs in spacious, modern facilities with meticulous testing at every phase. Employee numbers expand steadily. Branch offices multiply across nations. More than 1600 customers in 72 countries rely on our systems today. Rapid growth reflects committed effort and visible results. Comprehensive quality management oversees each component. The SMT pick and place machine for LED emerges fully prepared for intensive daily operation. We serve as a trusted global partner in electronics manufacturing.