RS-1R

JUKI

| Availability: | |

|---|---|

| Quantity: | |

| JUKI SMT Equipment

The JUKI SMT equipment forms the heart of modern SMT lines, where high-speed placement machines mount surface components with quiet precision across every board. In full production, these mounters connect printing, soldering, and inspection stages into one steady rhythm. RS-1R and RS-1XL models offer balanced versatility for varied board sizes, while RX-7R and RX-8 push exceptional output in limited space. Each carries proven heads, sharp imaging, and controls that operators master quickly. They handle automotive electronics, LED panels, and consumer devices with consistent results. I.C.T builds complete SMT assembly systems around them, from initial layout to daily operation, ensuring lines run smoothly and yield remains high year after year.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

The RS-1R delivers 47,000 CPH optimum with ±35µm accuracy and manages boards up to 650×370mm single or extended double-clamped sizes. The RS-1XL expands to 650×560mm, suited for wider applications such as LED assemblies. Both feature Takumi heads that adapt fluidly between tasks. They accommodate parts from 0201 metric to 74mm square or elongated shapes. Maximum feeders reach 112. Compact footprints allow seamless line integration. Vision systems detect errors early, while force control safeguards delicate work. These models thrive in facilities that require flexibility across mixed production runs. I.C.T configures them precisely to match existing workflows and future needs.

RX-7R / RX-8 Series Features

The RX-7R achieves 75,000 CPH on chips with P16 heads and near ±0.04mm precision, handling 03015 parts up to 25mm square across 510×450mm boards. The RX-8 advances to 100,000 CPH through the P20 head, excelling in dense, small-component placement. Both maintain a narrow 998mm width for efficient floor use. Dual-lane options and real-time monitoring reduce idle moments. Low-impact placement protects boards during rapid cycles. These machines suit high-volume environments—mobile devices, automotive modules, lighting—where maximum throughput in minimal space drives success. Their design delivers leading placement rates per square meter.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T assembles dependable PCBA assembly lines centered on the JUKI SMT equipment for consistent daily performance. Vacuum loaders introduce clean boards from the start. Automatic printers apply paste with exact control. The mounter places every component firmly and true. Multi-zone reflow ovens bond solder evenly and strong. AOI systems inspect closely to catch any flaw early. Conveyors maintain smooth, uninterrupted flow. Yield rises steadily while costs fall away. No unnecessary pauses or rework appear. Lines manage demanding work—automotive power units, LED assemblies, and beyond. Completed boards emerge prepared for final use. I.C.T supports the entire chain from beginning to end.

| Customer Success Video

A customer appears in the video describing their complete SMT and DIP lines dedicated to automotive power supply manufacturing. The SMT section begins with vacuum loading of clean boards, followed by cleaning, precise paste printing, and the JUKI SMT equipment mounting parts at high speed with clear accuracy. Boards proceed through conveyors, multi-zone reflow, cooling buffers, AOI inspection, and unloading stations. The DIP process includes wave soldering, board flipping, ICT testing, and secure connections. Footage reveals steady machine operation, smooth board movement, and precise placement throughout. The customer notes reduced defects, maintained high pace, and solid quality suitable for automotive demands. Downtime remains minimal in their regular production schedule.

| Service and Training Support

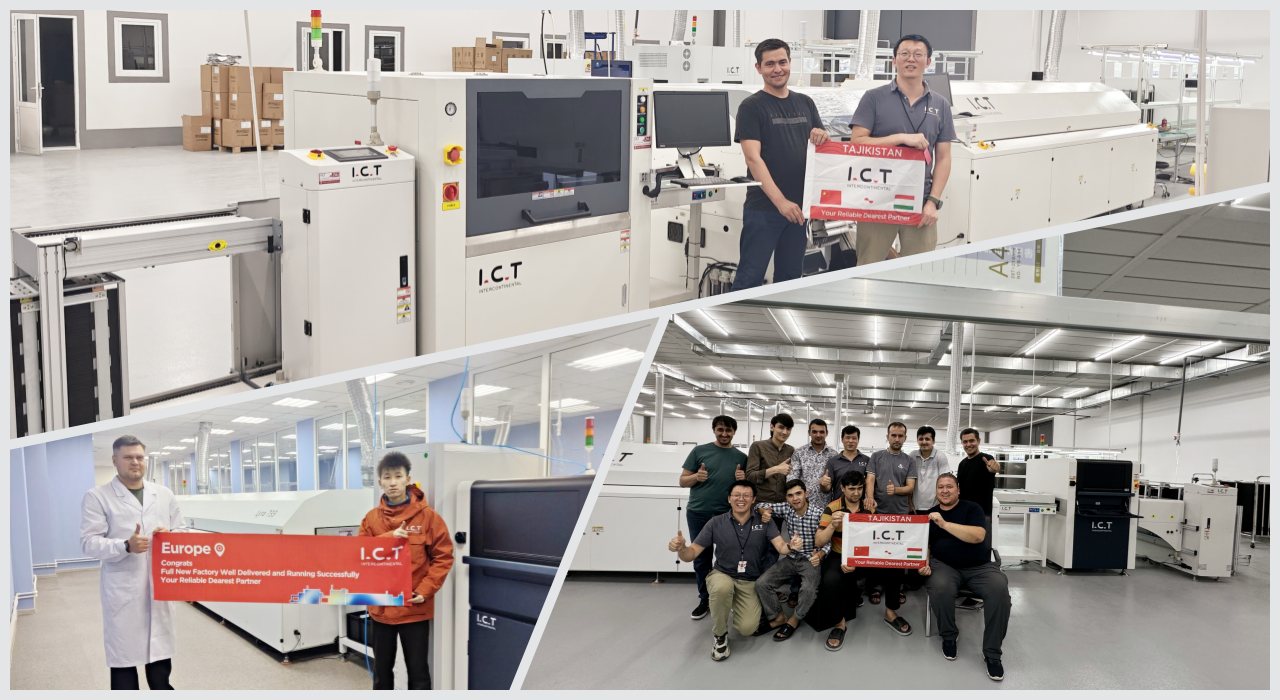

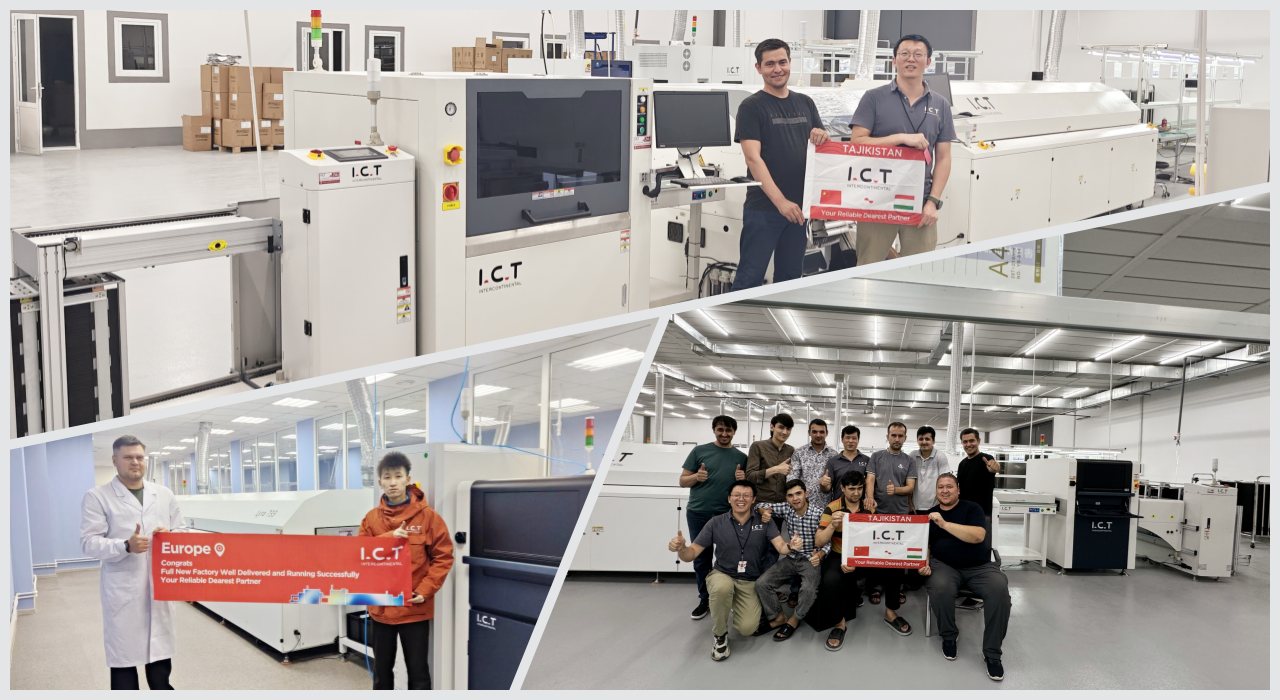

I.C.T delivers comprehensive support for entire factory lines built around JUKI SMT equipment. Experienced engineers arrive on site for careful installation and initial operation. They conduct thorough training sessions covering daily routines, program development, maintenance procedures, and basic troubleshooting. Remote diagnostics allow rapid resolution of issues from distant locations. Scheduled maintenance visits preserve peak performance over long periods. Technical teams assist with line reconfiguration, process refinement, or capacity increases without major disruption. Global service centers ensure prompt response wherever customers operate. This ongoing partnership transforms equipment into dependable assets that support steady growth and reliable output across full manufacturing systems.

| Customer Feedback

Customers frequently highlight the skill and promptness of I.C.T engineers during installation and problem resolution. They express satisfaction with the dependable speed and precision of JUKI SMT equipment through extended production runs. Secure, professional packing ensures machines reach facilities in perfect condition despite long-distance transport. Inquiries receive swift, detailed responses that prevent unnecessary delays. Many report smoother overall operations, higher yields, and fewer interruptions than anticipated. Confidence grows from consistent equipment performance combined with attentive, reliable support. Factories value I.C.T as a partner that contributes directly to efficient, high-quality manufacturing.

| Certifications and Standards

JUKI SMT equipment holds essential certifications including CE for European safety compliance, RoHS for environmentally responsible materials, and ISO9001 for structured quality management. Multiple patents protect innovative placement heads, vision systems, and related technologies. These credentials confirm adherence to international standards of safety, sustainability, and manufacturing consistency. Facilities worldwide install and operate the machines with assurance that regulatory requirements stay fulfilled. The certifications reflect a commitment to producing durable, high-performing equipment that meets demanding global expectations without compromise.

| About I.C.T Company and Factory

I.C.T maintains dedicated research and development teams focused on advancing SMT and related technologies. Production occurs in expansive facilities equipped with rigorous inspection at every stage, from component receipt to final assembly. Since establishment in 2012, the company has expanded rapidly, now employing a substantial workforce across multiple branches. More than 1600 customers in over 72 countries rely on I.C.T solutions. Strict quality management systems govern every process, ensuring consistent reliability and longevity. I.C.T offers complete factory-level support—from initial planning and full-line delivery to ongoing optimization and upgrades—helping electronics manufacturers achieve stable, efficient operations worldwide.

| JUKI SMT Equipment

The JUKI SMT equipment forms the heart of modern SMT lines, where high-speed placement machines mount surface components with quiet precision across every board. In full production, these mounters connect printing, soldering, and inspection stages into one steady rhythm. RS-1R and RS-1XL models offer balanced versatility for varied board sizes, while RX-7R and RX-8 push exceptional output in limited space. Each carries proven heads, sharp imaging, and controls that operators master quickly. They handle automotive electronics, LED panels, and consumer devices with consistent results. I.C.T builds complete SMT assembly systems around them, from initial layout to daily operation, ensuring lines run smoothly and yield remains high year after year.

| JUKI Pick and Place Machine Model Features

RS-1R / RS-1XL Series Features

The RS-1R delivers 47,000 CPH optimum with ±35µm accuracy and manages boards up to 650×370mm single or extended double-clamped sizes. The RS-1XL expands to 650×560mm, suited for wider applications such as LED assemblies. Both feature Takumi heads that adapt fluidly between tasks. They accommodate parts from 0201 metric to 74mm square or elongated shapes. Maximum feeders reach 112. Compact footprints allow seamless line integration. Vision systems detect errors early, while force control safeguards delicate work. These models thrive in facilities that require flexibility across mixed production runs. I.C.T configures them precisely to match existing workflows and future needs.

RX-7R / RX-8 Series Features

The RX-7R achieves 75,000 CPH on chips with P16 heads and near ±0.04mm precision, handling 03015 parts up to 25mm square across 510×450mm boards. The RX-8 advances to 100,000 CPH through the P20 head, excelling in dense, small-component placement. Both maintain a narrow 998mm width for efficient floor use. Dual-lane options and real-time monitoring reduce idle moments. Low-impact placement protects boards during rapid cycles. These machines suit high-volume environments—mobile devices, automotive modules, lighting—where maximum throughput in minimal space drives success. Their design delivers leading placement rates per square meter.

| Specification

| Parameter | RS-1R | RS-1XL | RX-7R | RX-8 |

|---|---|---|---|---|

| Placement Speed (Optimum CPH) | 47,000 | 42,000 | 75,000 | 100,000 |

| Maximum Board Size (mm) | 650 × 370 (single/double) | 650 × 560 | 510 × 450 (single lane) | 510 × 450 (approx.) |

| Minimum Board Size (mm) | 50 × 50 | 50 × 50 | 50 × 50 | 50 × 50 |

| Component Height (max mm) | 25 | 25 | 3-10.5 (head dependent) | 3 |

| Smallest Component | 0201 (metric) | 0201 (metric) | 03015 (metric) | 0201 (approx. 0.4×0.2mm) |

| Largest Component (mm) | 74 square / 150×50 | 74 square / 150×50 | 25 square | 5 square |

| Feeder Inputs (max) | 112 | 112 | 76 | 56 (approx.) |

| Placement Accuracy | ±35µm (Cpk ≥1) | ±35µm (Cpk ≥1) | ±40µm (approx.) | High precision (vision) |

| Machine Width (mm) | 1,500 (approx.) | 2,109 | 998 | 998 |

| Head Type | Takumi inline head | Takumi inline head | Parallel rotary heads (P16S) | P20 rotary head |

| SMT Line Equipment List

I.C.T assembles dependable PCBA assembly lines centered on the JUKI SMT equipment for consistent daily performance. Vacuum loaders introduce clean boards from the start. Automatic printers apply paste with exact control. The mounter places every component firmly and true. Multi-zone reflow ovens bond solder evenly and strong. AOI systems inspect closely to catch any flaw early. Conveyors maintain smooth, uninterrupted flow. Yield rises steadily while costs fall away. No unnecessary pauses or rework appear. Lines manage demanding work—automotive power units, LED assemblies, and beyond. Completed boards emerge prepared for final use. I.C.T supports the entire chain from beginning to end.

| Customer Success Video

A customer appears in the video describing their complete SMT and DIP lines dedicated to automotive power supply manufacturing. The SMT section begins with vacuum loading of clean boards, followed by cleaning, precise paste printing, and the JUKI SMT equipment mounting parts at high speed with clear accuracy. Boards proceed through conveyors, multi-zone reflow, cooling buffers, AOI inspection, and unloading stations. The DIP process includes wave soldering, board flipping, ICT testing, and secure connections. Footage reveals steady machine operation, smooth board movement, and precise placement throughout. The customer notes reduced defects, maintained high pace, and solid quality suitable for automotive demands. Downtime remains minimal in their regular production schedule.

| Service and Training Support

I.C.T delivers comprehensive support for entire factory lines built around JUKI SMT equipment. Experienced engineers arrive on site for careful installation and initial operation. They conduct thorough training sessions covering daily routines, program development, maintenance procedures, and basic troubleshooting. Remote diagnostics allow rapid resolution of issues from distant locations. Scheduled maintenance visits preserve peak performance over long periods. Technical teams assist with line reconfiguration, process refinement, or capacity increases without major disruption. Global service centers ensure prompt response wherever customers operate. This ongoing partnership transforms equipment into dependable assets that support steady growth and reliable output across full manufacturing systems.

| Customer Feedback

Customers frequently highlight the skill and promptness of I.C.T engineers during installation and problem resolution. They express satisfaction with the dependable speed and precision of JUKI SMT equipment through extended production runs. Secure, professional packing ensures machines reach facilities in perfect condition despite long-distance transport. Inquiries receive swift, detailed responses that prevent unnecessary delays. Many report smoother overall operations, higher yields, and fewer interruptions than anticipated. Confidence grows from consistent equipment performance combined with attentive, reliable support. Factories value I.C.T as a partner that contributes directly to efficient, high-quality manufacturing.

| Certifications and Standards

JUKI SMT equipment holds essential certifications including CE for European safety compliance, RoHS for environmentally responsible materials, and ISO9001 for structured quality management. Multiple patents protect innovative placement heads, vision systems, and related technologies. These credentials confirm adherence to international standards of safety, sustainability, and manufacturing consistency. Facilities worldwide install and operate the machines with assurance that regulatory requirements stay fulfilled. The certifications reflect a commitment to producing durable, high-performing equipment that meets demanding global expectations without compromise.

| About I.C.T Company and Factory

I.C.T maintains dedicated research and development teams focused on advancing SMT and related technologies. Production occurs in expansive facilities equipped with rigorous inspection at every stage, from component receipt to final assembly. Since establishment in 2012, the company has expanded rapidly, now employing a substantial workforce across multiple branches. More than 1600 customers in over 72 countries rely on I.C.T solutions. Strict quality management systems govern every process, ensuring consistent reliability and longevity. I.C.T offers complete factory-level support—from initial planning and full-line delivery to ongoing optimization and upgrades—helping electronics manufacturers achieve stable, efficient operations worldwide.