I.C.T pcb smt bareboard loader delivers fast, gentle, and fully automatic bare-board feeding for any high-speed SMT line.

a. Heavy-duty construction meets full CE and ISO standards

b. Top-grade electrical parts for zero-error precision

c. Industry 4.0-ready control, easy to expand

d. Ergonomic design cuts operator fatigue dramatically

e. Perfect magazine handling with zero board damage

f. Seamless SMEMA and smart-factory connectivity

g. Worldwide on-site service and 24/7 instant support

SMT PCB Loader / Unloader

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Reliable pcb smt bareboard loader for High-Volume SMT Production

The upgraded I.C.T pcb smt bareboard loader is the go-to SMT board loading machine when you need rock-solid automatic bare-board feeding. It gently lifts PCBs from magazines and sends them perfectly aligned to the printer or placement machine—no scratches, no misfeeds. Available in standard or full CE versions, this pcb smt bareboard loader packs stronger hardware, smarter electrical systems, and future-proof Industry 4.0 controls to slash downtime and boost daily output. It integrates instantly with any major brand and supports full smart-factory connectivity while keeping your line running 24/7 with zero hassle.

| Detailed Product Features

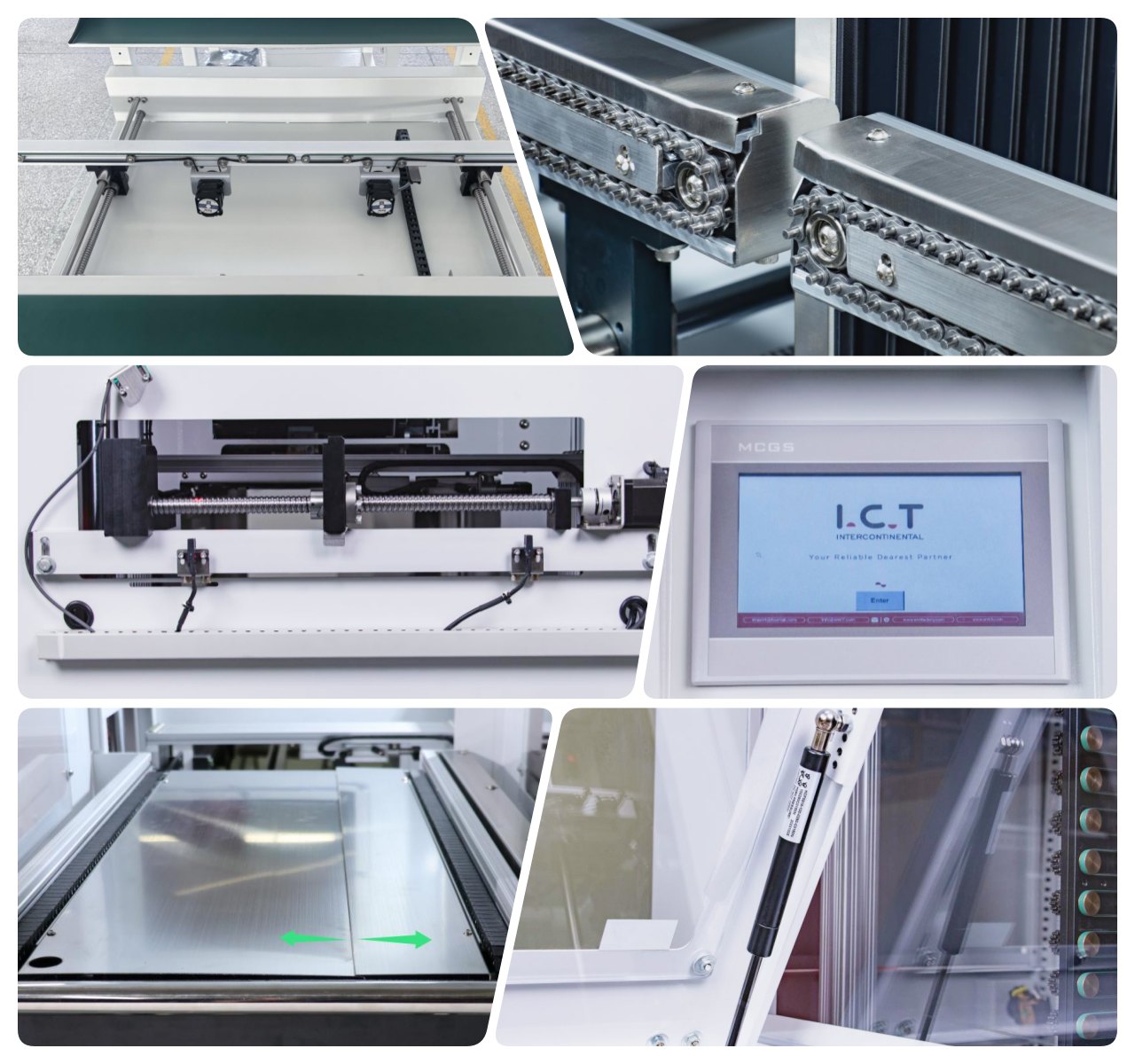

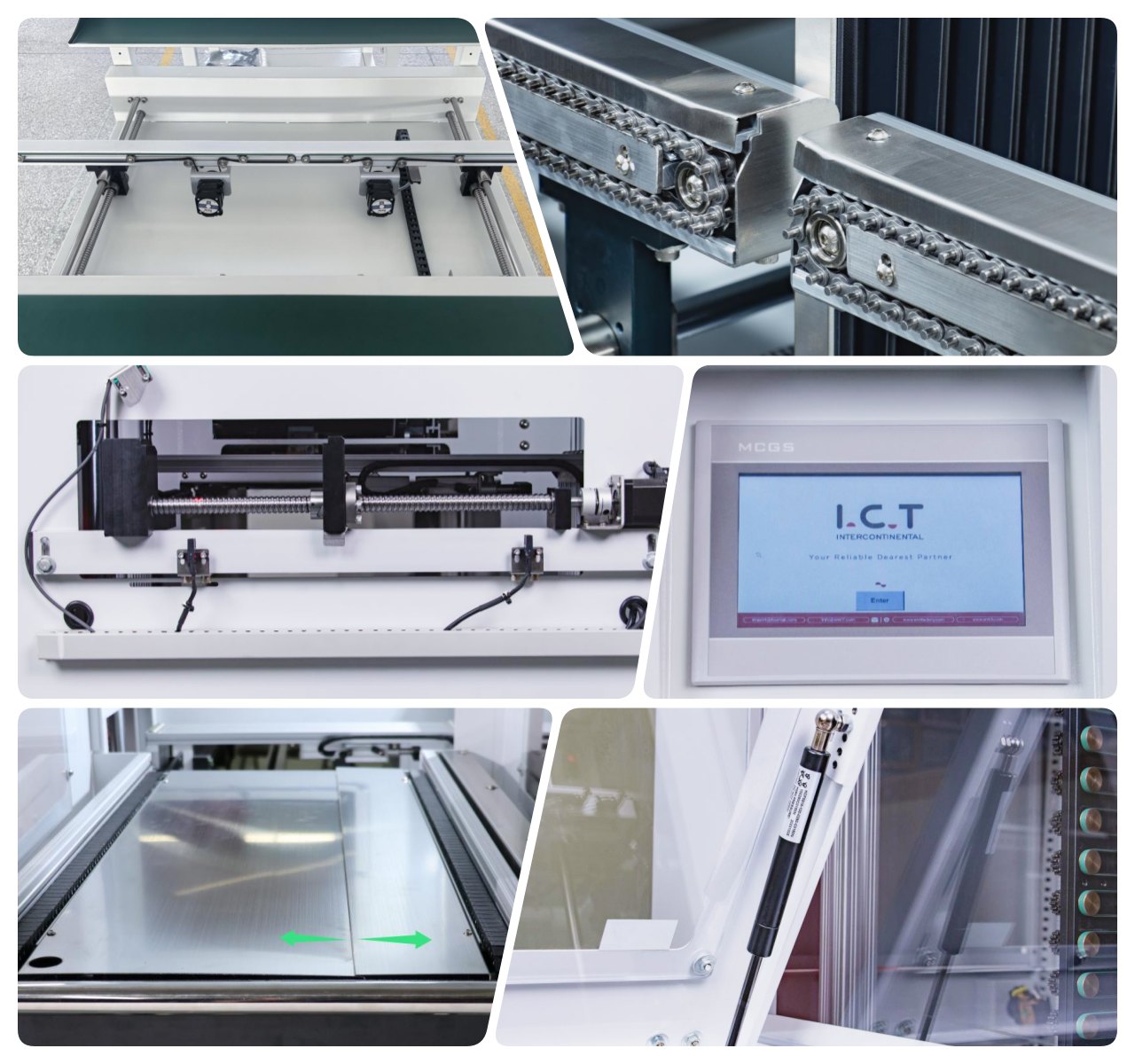

Every rail, lift, and frame on the pcb smt bareboard loader uses upgraded high-grade materials and follows strict ISO and CE standards. The reinforced base and ergonomic layout deliver years of vibration-free stability and make daily operation and maintenance a breeze for any technician.

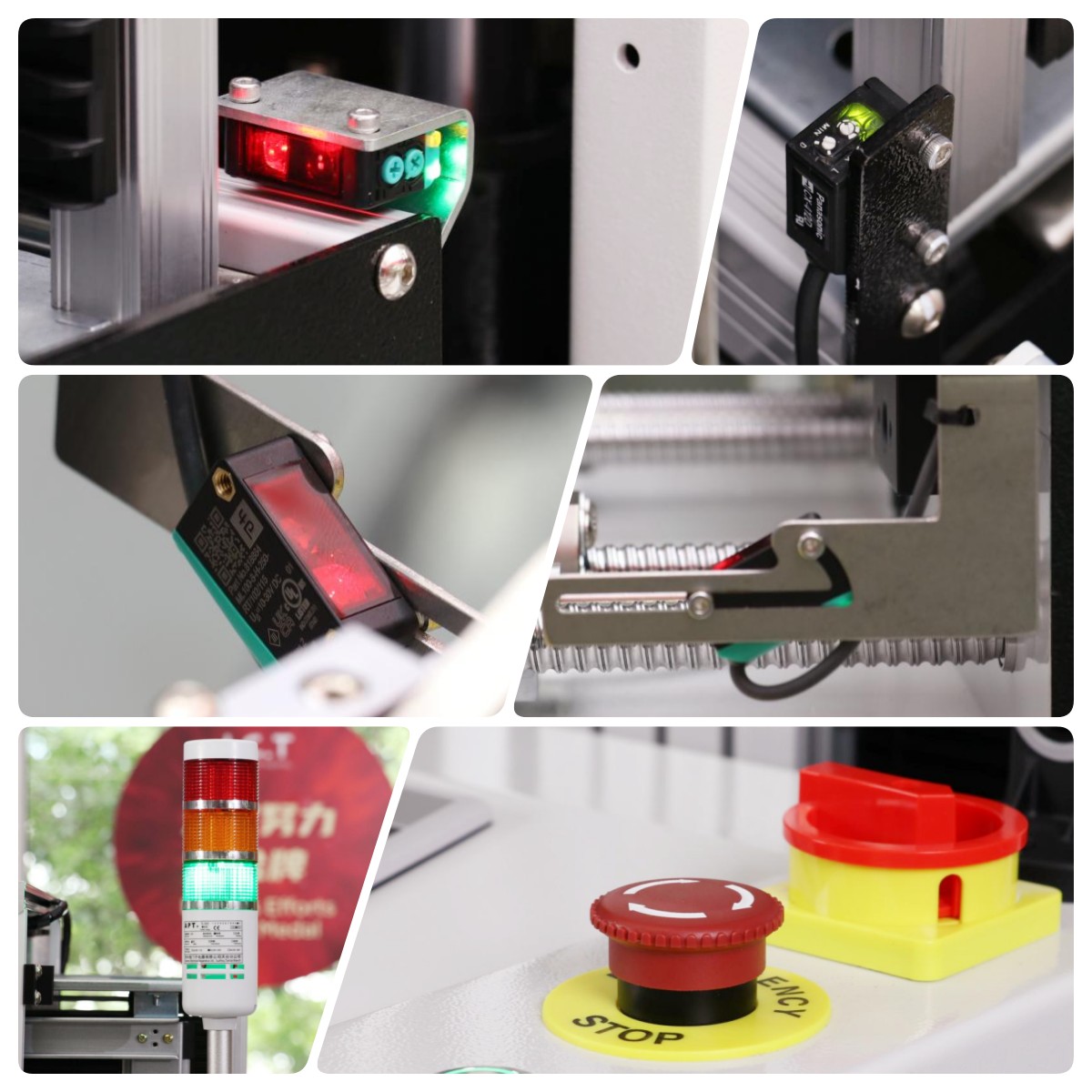

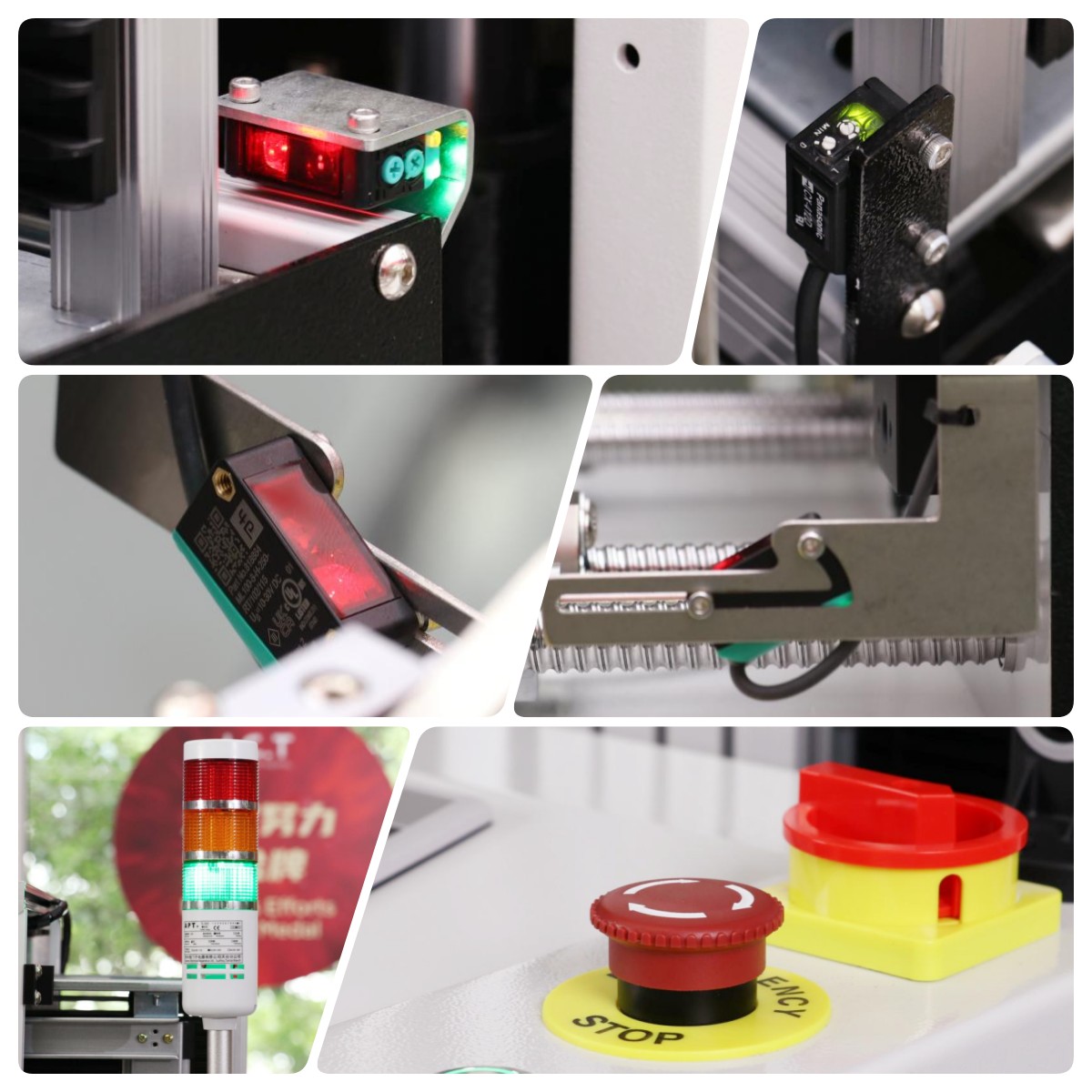

Premium sensors, bright tower lights, and high-frequency buttons give the pcb smt bareboard loader instant board detection and crystal-clear status feedback. Operators stay in full control even on the fastest lines, eliminating errors and keeping production at peak speed.

The expandable control platform supports IPC-CFX, Hermes, and SEMI SMT-ELS protocols (optional). Connecting the SMT board loading machine to your factory MES or adding new features takes just minutes, instantly turning your line into a true smart-factory solution.

Precision pusher and lifting mechanisms handle all magazine sizes quietly and smoothly. The pcb smt bareboard loader guarantees every board arrives perfectly positioned—protecting bare-board quality right from the very first process step.

Optional modules let the pcb smt bareboard loader talk directly to printers, placement machines, and AOI systems. Plug-and-play SMEMA plus optional smart protocols mean zero rework and maximum flexibility for any SMT setup.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our turnkey High-Quality SMT Production Line delivers fully automatic, high-speed, ultra-reliable PCBA manufacturing from bare board to final inspection. It starts with the flawless pcb smt bareboard loader, flows through precision printing and high-speed placement, continues with stable reflow soldering, and ends with advanced AOI—all perfectly connected. Labor stays low, first-pass yield stays sky-high, and uptime stays exceptional. This proven solution meets automotive, medical, consumer electronics, and LED standards while keeping operating costs rock-bottom.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

I.C.T overseas engineers flew to Finland to install and commission a fully automatic LED Panel production line for a leading European lighting manufacturer. The turnkey solution included our pcb smt bareboard loader, 1.5 m fully automatic printer, SM482PLUS placement machine, L8 reflow oven, vertical cooling buffer, linking conveyors, board splitter, and solder paste mixer. Our team finished installation, debugging, and hands-on operator training in just five days. On the first official production day the line already hit target speed with zero defects. The customer especially praised the rock-solid performance of the pcb smt bareboard loader and the perfect machine-to-machine communication. They passed the strict European audit on the first try and immediately placed a repeat order for another line.

| Professional Training & Support

From remote pre-install checks to on-site commissioning, free operator and maintenance training, 24/7 global hotline, stocked spare-parts warehouses worldwide, and scheduled preventive maintenance—I.C.T makes sure your pcb smt bareboard loader runs at peak efficiency year after year with almost zero unplanned downtime.

| Customer Praise

“Your engineer fixed our issue at 3 a.m. local time—fastest response ever!” “Packing survived 45 days at sea—machine arrived perfect, zero damage.” “We’ve run the pcb smt bareboard loader 24/7 for 21 months—no breakdowns.” “Training was so clear our new operators were independent after one shift.”

| Our Certification

Every pcb smt bareboard loader carries CE, RoHS, ISO9001 certifications plus multiple proprietary patents. Before shipping, each unit completes a full 72-hour loaded burn-in test and detailed quality inspection, guaranteeing you receive proven reliability and full compliance right from day one.

| About Us and Factory

Since 2012, I.C.T has grown into a modern 12,000 m² facility with nearly 90 team members and our own R&D center. We design, manufacture, and test everything in-house under strict quality systems. Serving over 1,600 customers across 72 countries, we’ve earned trust by always delivering—from a single pcb smt bareboard loader to complete turnkey lines.

| Reliable pcb smt bareboard loader for High-Volume SMT Production

The upgraded I.C.T pcb smt bareboard loader is the go-to SMT board loading machine when you need rock-solid automatic bare-board feeding. It gently lifts PCBs from magazines and sends them perfectly aligned to the printer or placement machine—no scratches, no misfeeds. Available in standard or full CE versions, this pcb smt bareboard loader packs stronger hardware, smarter electrical systems, and future-proof Industry 4.0 controls to slash downtime and boost daily output. It integrates instantly with any major brand and supports full smart-factory connectivity while keeping your line running 24/7 with zero hassle.

| Detailed Product Features

Every rail, lift, and frame on the pcb smt bareboard loader uses upgraded high-grade materials and follows strict ISO and CE standards. The reinforced base and ergonomic layout deliver years of vibration-free stability and make daily operation and maintenance a breeze for any technician.

Premium sensors, bright tower lights, and high-frequency buttons give the pcb smt bareboard loader instant board detection and crystal-clear status feedback. Operators stay in full control even on the fastest lines, eliminating errors and keeping production at peak speed.

The expandable control platform supports IPC-CFX, Hermes, and SEMI SMT-ELS protocols (optional). Connecting the SMT board loading machine to your factory MES or adding new features takes just minutes, instantly turning your line into a true smart-factory solution.

Precision pusher and lifting mechanisms handle all magazine sizes quietly and smoothly. The pcb smt bareboard loader guarantees every board arrives perfectly positioned—protecting bare-board quality right from the very first process step.

Optional modules let the pcb smt bareboard loader talk directly to printers, placement machines, and AOI systems. Plug-and-play SMEMA plus optional smart protocols mean zero rework and maximum flexibility for any SMT setup.

| Specification

| Parameter | Specification |

|---|---|

| PCB Width | 50–400 mm (500 mm optional) |

| Conveyor Height | 900 ± 20 mm |

| Transfer Speed | 0.5–20 m/min adjustable |

| Power Supply | AC 220 V 50/60 Hz |

| Power Consumption | 50–150 W |

| Direction | Left to Right (Right to Left optional) |

| Belt Material | 3 mm ESD flat belt or chain |

| Control Mode | PLC + Touch Screen |

| One-button Width Adjust | Optional (whole line sync) |

| CE Safety Standard | Full cover + sensor protection |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

| SMT Line Equipment List

Our turnkey High-Quality SMT Production Line delivers fully automatic, high-speed, ultra-reliable PCBA manufacturing from bare board to final inspection. It starts with the flawless pcb smt bareboard loader, flows through precision printing and high-speed placement, continues with stable reflow soldering, and ends with advanced AOI—all perfectly connected. Labor stays low, first-pass yield stays sky-high, and uptime stays exceptional. This proven solution meets automotive, medical, consumer electronics, and LED standards while keeping operating costs rock-bottom.

| Product Name | Purpose in SMT Line |

|---|---|

| SMT Line | Turkey Fully Automated Traceable High-End SMT Line. |

| PCB Loader | Automatically loads bare PCBs to the line. |

| Solder Paste Printer | Prints solder paste on PCB pads accurately. |

| Pick and Place Machine | Mounts components onto PCBs precisely. |

| Reflow Oven | Melts solder to form solid joints. |

| Inspection Machine | SMT inspection devices like AOI, SPI, X-ray, and stencil inspecter. |

| Traceability Equipment | Records and tracks production data. |

| SMT Peripheral | Auxiliary SMT equipment like IC programmers, storage, X-ray counters, and tape splicers |

| PCB Cleaning Machine | Cleans PCB/Stencil to remove flux, dust, and contaminants post-soldering. |

| PCB Routing Machine | Precision-cuts PCBA outlines and slots with high-speed cutting. |

| SMT Bentop Robot | Automates screw-fastening and soldering for efficient SMT assembly. |

| Customer Success Story

I.C.T overseas engineers flew to Finland to install and commission a fully automatic LED Panel production line for a leading European lighting manufacturer. The turnkey solution included our pcb smt bareboard loader, 1.5 m fully automatic printer, SM482PLUS placement machine, L8 reflow oven, vertical cooling buffer, linking conveyors, board splitter, and solder paste mixer. Our team finished installation, debugging, and hands-on operator training in just five days. On the first official production day the line already hit target speed with zero defects. The customer especially praised the rock-solid performance of the pcb smt bareboard loader and the perfect machine-to-machine communication. They passed the strict European audit on the first try and immediately placed a repeat order for another line.

| Professional Training & Support

From remote pre-install checks to on-site commissioning, free operator and maintenance training, 24/7 global hotline, stocked spare-parts warehouses worldwide, and scheduled preventive maintenance—I.C.T makes sure your pcb smt bareboard loader runs at peak efficiency year after year with almost zero unplanned downtime.

| Customer Praise

“Your engineer fixed our issue at 3 a.m. local time—fastest response ever!” “Packing survived 45 days at sea—machine arrived perfect, zero damage.” “We’ve run the pcb smt bareboard loader 24/7 for 21 months—no breakdowns.” “Training was so clear our new operators were independent after one shift.”

| Our Certification

Every pcb smt bareboard loader carries CE, RoHS, ISO9001 certifications plus multiple proprietary patents. Before shipping, each unit completes a full 72-hour loaded burn-in test and detailed quality inspection, guaranteeing you receive proven reliability and full compliance right from day one.

| About Us and Factory

Since 2012, I.C.T has grown into a modern 12,000 m² facility with nearly 90 team members and our own R&D center. We design, manufacture, and test everything in-house under strict quality systems. Serving over 1,600 customers across 72 countries, we’ve earned trust by always delivering—from a single pcb smt bareboard loader to complete turnkey lines.