I.C.T

| Availability: | |

|---|---|

| Quantity: | |

| Advanced Hot Melt Glue Dispenser

The hot melt glue dispenser enters service with quiet authority. Servo motors engage smoothly. Vision system locates reference points instantly. Valve dispenses measured amounts. Preheating ensures consistent flow. Syringes change without delay. Machine operates through long shifts. Boards receive accurate glue patterns. Components bond securely. Production continues reliably. Engineers monitor performance. Results meet specifications. Global network provides assistance when required. Equipment proves its value in daily operation.

| Detailed Product Features

Valve controls glue release precisely. Servo and screw drive maintain accuracy. Preheating stabilizes material temperature. Supports multiple adhesive types effectively. Syringe changes completed rapidly. Automatic purge keeps system clear. Bonds achieve required strength consistently. The hot melt glue dispenser performs with professional reliability.

Boards move on anti-static belts. Independent motors control movement. Stop mechanism secures position. Width adjustment preserves alignment. Handles different board sizes and weights. Transport directions flexible. The hot melt glue dispenser integrates smoothly into production flow.

Cleaning cycle activates simply. Short duration clears valve. Temperature control maintains glue properties. Minimal intervention needed. The hot melt glue dispenser prepares quickly for continued use.

PLC manages operations with computer support. Premium components selected. Standards compliance verified. Expansion options available. Interface designed for ease. The hot melt glue dispenser functions efficiently in factory environment.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Boards enter system automatically. Hot melt glue dispenser applies adhesive accurately. Components placed on prepared surfaces. Curing stations harden bonds rapidly. Inspection performed as needed. Stations operate in sequence. Limited operators sufficient. Yield rates consistently high. Suitable for automotive, medical, and LED production. Full line supplied with unified support.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Curing Oven | Rapidly cures glue with IR or UV technology |

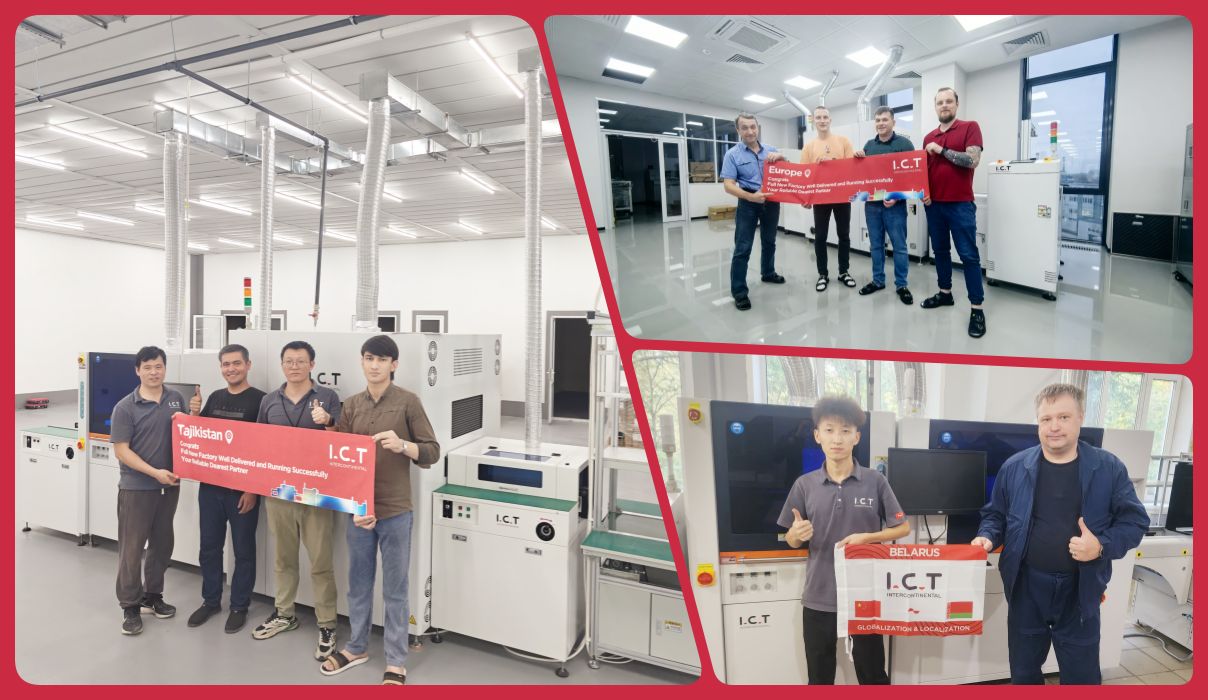

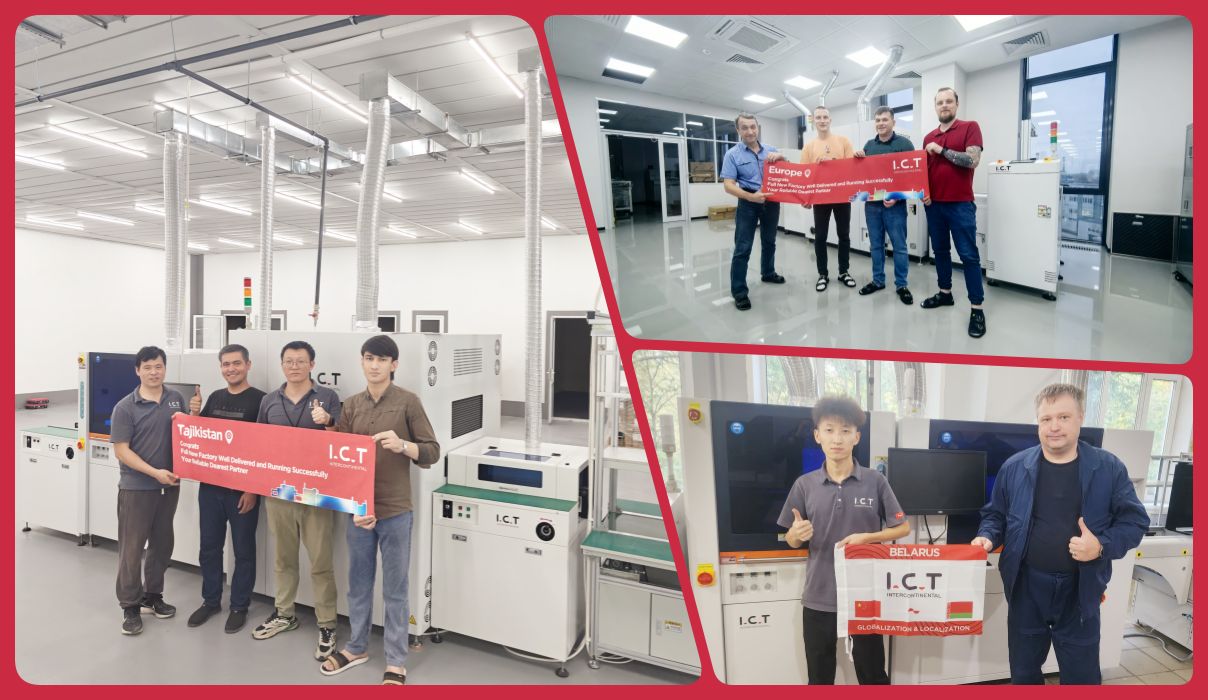

| Customer Success Story

Two engineers deployed to Tajikistan site. Customer acquired several lines including SMT, DIP, coating, dispensing, and LED bulb assembly. Installation proceeded methodically. Hot melt glue dispenser achieved accurate placement immediately. Components positioned correctly. Curing completed. Inspection approved. Local operators trained comprehensively. Production commenced at full rate. Customer reviewed results and confirmed expectations met.

| Professional Training & Support

Personnel arrive with each hot melt glue dispenser. Training provided until customer independence confirmed. Remote support resolves issues efficiently. Parts supplied from international stocks. On-site response prompt. Updates delivered regularly. The hot melt glue dispenser supports sustained production performance.

| Customer Praise

Engineers recognized for expertise. Equipment valued for reliability. Packaging ensured safe arrival. Technical responses timely. General satisfaction expressed.

| Our Certification

CE certification obtained. RoHS compliance achieved. ISO9001 standard held. Patents registered. Hot melt glue dispenser meets global requirements.

| About Us and Factory

n-house research and manufacturing in Dongguan. Facility covers 12 000 m². Staff numbers 89 including 20 engineers. Operations expanded since 2012. Serves more than 1 600 customers across 72 countries. Testing procedures thorough. Quality systems rigorous.

| Advanced Hot Melt Glue Dispenser

The hot melt glue dispenser enters service with quiet authority. Servo motors engage smoothly. Vision system locates reference points instantly. Valve dispenses measured amounts. Preheating ensures consistent flow. Syringes change without delay. Machine operates through long shifts. Boards receive accurate glue patterns. Components bond securely. Production continues reliably. Engineers monitor performance. Results meet specifications. Global network provides assistance when required. Equipment proves its value in daily operation.

| Detailed Product Features

Valve controls glue release precisely. Servo and screw drive maintain accuracy. Preheating stabilizes material temperature. Supports multiple adhesive types effectively. Syringe changes completed rapidly. Automatic purge keeps system clear. Bonds achieve required strength consistently. The hot melt glue dispenser performs with professional reliability.

Boards move on anti-static belts. Independent motors control movement. Stop mechanism secures position. Width adjustment preserves alignment. Handles different board sizes and weights. Transport directions flexible. The hot melt glue dispenser integrates smoothly into production flow.

Cleaning cycle activates simply. Short duration clears valve. Temperature control maintains glue properties. Minimal intervention needed. The hot melt glue dispenser prepares quickly for continued use.

PLC manages operations with computer support. Premium components selected. Standards compliance verified. Expansion options available. Interface designed for ease. The hot melt glue dispenser functions efficiently in factory environment.

| Specification

| Model | I.C.T-D450 | I.C.T-D600(LENS) | I.C.T-D1200(LENS) |

| Dispensing Range | X400*Y400*Z50mm | X600*Y400*Z50mm | X1200*Y400*Z50mm |

| Product Weight | Max.4.5kg | ||

| Product Thickness | Max.6mm | ||

| Maximum Speed | 2000mm/s | ||

| Vision Methodology | CCD | ||

| Cleaning System | Auto | ||

| Injection Valve Speed | 200 points/s | ||

| Dispensing Accuracy | ±0.02mm | ||

| Repeated Accuracy | ±0.01mm | ||

| Weight | 650 Kg | 750 Kg | 950 Kg |

| Dimension | W770*D1200*H1500mm | W880*D1200*H1500mm | W1590*D1200*H1500mm |

| SMT Line Equipment List

Boards enter system automatically. Hot melt glue dispenser applies adhesive accurately. Components placed on prepared surfaces. Curing stations harden bonds rapidly. Inspection performed as needed. Stations operate in sequence. Limited operators sufficient. Yield rates consistently high. Suitable for automotive, medical, and LED production. Full line supplied with unified support.

| Product Name | Purpose in Glue Dispensing Line |

|---|---|

| Glue Dispensing Machine | Delivers high-speed, ultra-precise glue dispensing |

| Conformal Coating Machine | Applies final protective coating for reliability |

| Pick and Place Machine | Accurately places components onto fresh glue |

| Curing Oven | Rapidly cures glue with IR or UV technology |

| Customer Success Story

Two engineers deployed to Tajikistan site. Customer acquired several lines including SMT, DIP, coating, dispensing, and LED bulb assembly. Installation proceeded methodically. Hot melt glue dispenser achieved accurate placement immediately. Components positioned correctly. Curing completed. Inspection approved. Local operators trained comprehensively. Production commenced at full rate. Customer reviewed results and confirmed expectations met.

| Professional Training & Support

Personnel arrive with each hot melt glue dispenser. Training provided until customer independence confirmed. Remote support resolves issues efficiently. Parts supplied from international stocks. On-site response prompt. Updates delivered regularly. The hot melt glue dispenser supports sustained production performance.

| Customer Praise

Engineers recognized for expertise. Equipment valued for reliability. Packaging ensured safe arrival. Technical responses timely. General satisfaction expressed.

| Our Certification

CE certification obtained. RoHS compliance achieved. ISO9001 standard held. Patents registered. Hot melt glue dispenser meets global requirements.

| About Us and Factory

n-house research and manufacturing in Dongguan. Facility covers 12 000 m². Staff numbers 89 including 20 engineers. Operations expanded since 2012. Serves more than 1 600 customers across 72 countries. Testing procedures thorough. Quality systems rigorous.