MES System

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

Overview

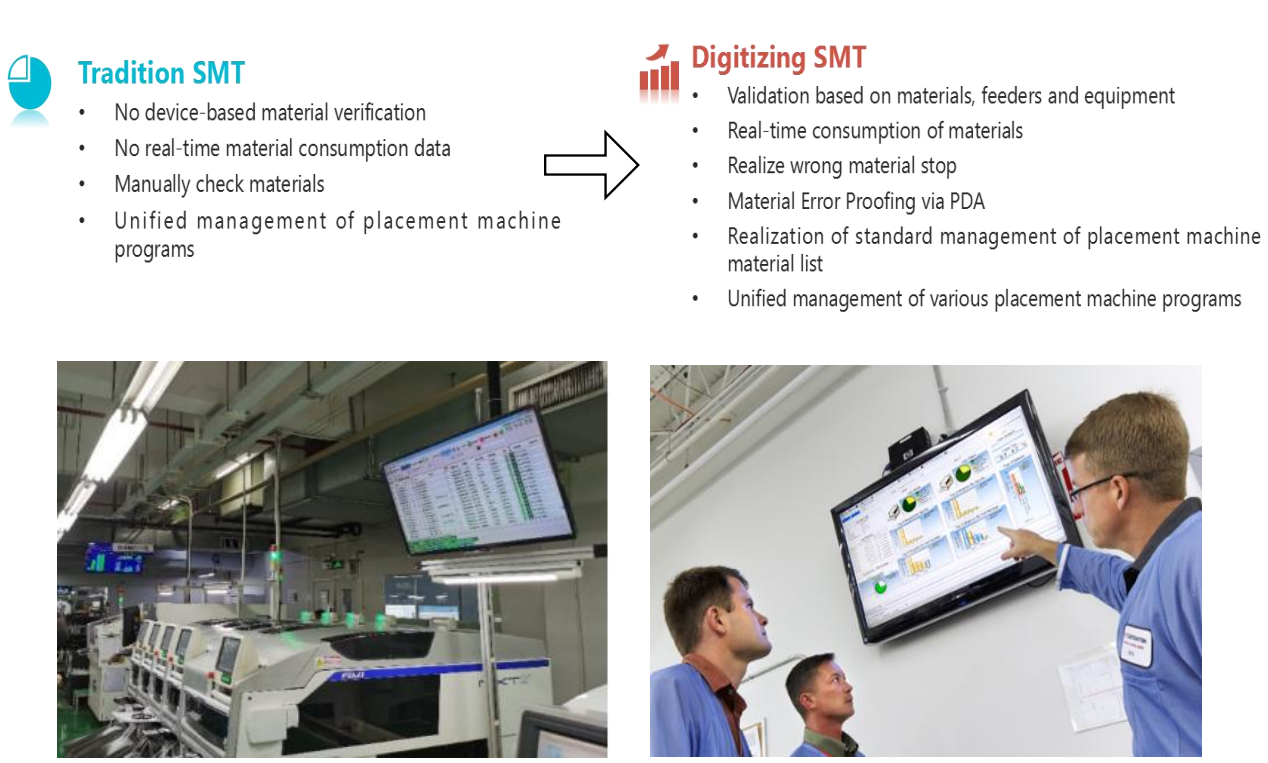

I.C.T Smart Factory solution can integrate management functions such as production scheduling, product tracking, quality control, equipment failure analysis, network report and so on on a unified platform. Using a unified database and network connection, it can provide workshop management information services for production department, quality inspection department, process department, logistics department and so on. MES system solution helps enterprises to implement complete closed-loop production, intelligent manufacturing and intelligent management by emphasizing the overall optimization of the manufacturing process.

The MES system can be used in SMT and DIP production equipment, and the devices that can be applied are:

SMT Machine: Stencil Printer, Pick and Place Machine, Reflow Oven.

2. DIP Machine: Automatic insterting Machine, Wave Soldering Machine, Selective Wave Soldering Machine.

3. Inspection Machine: AOI, SPI.

4. PCB Handling Machine: Loader and Unloader, Conveyor, Buffer etc.

5. PCB Protector: Coating Machine, Dispensing Machine, glue curing oven.

6. Traceability Equipment: Laser Marking Machine, Inkjet Printing Machine, Label Mounter.

1. Production process management: Products from the birth of the bar code to the whole production process, finished product delivery, the whole process without gap control; equipment error prevention and traceability; paperless electronic SOP; pull logistics and distribution.

2. Production scheduling management: effectively schedule production according to basic settings and constraints such as personnel, machine, line and product standard working hours.

3. Whole process quality control: Through multi-level quality early warning mechanism to timely feedback, track and deal with quality anomalies in the production process; automatically analyze quality data and generate multi-dimensional quality analysis reports, such as SPC statistical analysis report; automatic early warning and downtime mechanism can effectively prevent the occurrence of batch quality problems.

4. Visual management: Visual management tools monitor production progress, quality status, equipment status and efficiency in the whole process, feedback production problems in real time, and realize automatic push of electronic Kanban and mail.

5. BI data Center: Through the unified BI data center platform, we can efficiently analyze the data collected in the production process and generate multi-level and multi-dimensional management reports, such as plan achievement rate, output rate, through rate, bad analysis report, equipment operation rate (OEE), personnel efficiency and material loss rate, etc.

6. Equipment and fixture management: Based on the idea of lean TPM to carry out comprehensive control of equipment and fixture, reduce abnormal shutdown caused by equipment and mold failures, improve equipment OEE and improve production efficiency.

7. Production traceability: Through the bar code, effectively achieve human, machine, material and other information positive direction traceability.

8. Intelligent warehouse management: Through material bar coding, material IQC inspection, material collection, material delivery, material return, scrap, allocation, inventory and other efficient operations are carried out.

*Through the digitization of on-site manufacturing, a transparent real-time electronic display is formed. Display various Electronic display screen in turn through the slide mode, provide predictable data information, and grasp the production status in real time, Daily, hourly, weekly and monthly reports and analysis throughout the plant provide data support for daily production operations.

*Query data at the meeting or in real time, automatically send electronic reports by email according to the order number or based on the production situation, can determine the completion rate according to the set standard production capacity, and issue an unfinished reminder.

MES can be divided into three versions. You can choose different versions according to your own needs to achieve docking with different devices to achieve the scope of management. You can also choose the most basic version, gradually improve it, and upgrade.

1. Standard Edition: Including System Management, Basic Modeling, Warehouse Management, Production Management, Quality Management, Report Electronic Display Screen, a total of 6 groups of functions and 33 modules, mainly used for production line management.

2. Premium Edition: Including System Management, Basic Modeling, Warehouse Management, Production Management, Quality Management, Report Electronic Display Screen, a total of 6 groups of functions and 50 modules, mainly used for production line management, warehouse in and out material management.

3. Enterprise Synergistic Version: Including System Management, Supplier Collaboration, Basic Modeling, Warehouse Management, Production Management, System Integration, Quality Management, Report Electronic Display Screen, a total of 8 groups of functions and 65 modules, mainly used for the internal operation of the entire company and the management of external suppliers.

| Module | Product Description | Standard | Premium | Synergistic |

| System Management | Organizational Structure | √ | √ | √ |

| User Management | √ | √ | √ | |

| Role Management | √ | √ | √ | |

| Menu Management | √ | √ | √ | |

| Email Push | √ | √ | √ | |

| Basic Modeling | Factory Resources | √ | √ | √ |

| Business Relationship | √ | √ | √ | |

| Bar Code Rules | √ | √ | √ | |

| Tag Management | √ | √ | √ | |

| Error Code Library | √ | √ | √ | |

| Process Modeling | √ | √ | √ | |

| Standard Working Hours | √ | √ | √ | |

| Personnel Settings | √ | √ | √ | |

| Process Settings | √ | √ | √ |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

* In addition to the main equipment, there are peripheral equipment configured by the main equipment.

Overview

I.C.T Smart Factory solution can integrate management functions such as production scheduling, product tracking, quality control, equipment failure analysis, network report and so on on a unified platform. Using a unified database and network connection, it can provide workshop management information services for production department, quality inspection department, process department, logistics department and so on. MES system solution helps enterprises to implement complete closed-loop production, intelligent manufacturing and intelligent management by emphasizing the overall optimization of the manufacturing process.

The MES system can be used in SMT and DIP production equipment, and the devices that can be applied are:

SMT Machine: Stencil Printer, Pick and Place Machine, Reflow Oven.

2. DIP Machine: Automatic insterting Machine, Wave Soldering Machine, Selective Wave Soldering Machine.

3. Inspection Machine: AOI, SPI.

4. PCB Handling Machine: Loader and Unloader, Conveyor, Buffer etc.

5. PCB Protector: Coating Machine, Dispensing Machine, glue curing oven.

6. Traceability Equipment: Laser Marking Machine, Inkjet Printing Machine, Label Mounter.

1. Production process management: Products from the birth of the bar code to the whole production process, finished product delivery, the whole process without gap control; equipment error prevention and traceability; paperless electronic SOP; pull logistics and distribution.

2. Production scheduling management: effectively schedule production according to basic settings and constraints such as personnel, machine, line and product standard working hours.

3. Whole process quality control: Through multi-level quality early warning mechanism to timely feedback, track and deal with quality anomalies in the production process; automatically analyze quality data and generate multi-dimensional quality analysis reports, such as SPC statistical analysis report; automatic early warning and downtime mechanism can effectively prevent the occurrence of batch quality problems.

4. Visual management: Visual management tools monitor production progress, quality status, equipment status and efficiency in the whole process, feedback production problems in real time, and realize automatic push of electronic Kanban and mail.

5. BI data Center: Through the unified BI data center platform, we can efficiently analyze the data collected in the production process and generate multi-level and multi-dimensional management reports, such as plan achievement rate, output rate, through rate, bad analysis report, equipment operation rate (OEE), personnel efficiency and material loss rate, etc.

6. Equipment and fixture management: Based on the idea of lean TPM to carry out comprehensive control of equipment and fixture, reduce abnormal shutdown caused by equipment and mold failures, improve equipment OEE and improve production efficiency.

7. Production traceability: Through the bar code, effectively achieve human, machine, material and other information positive direction traceability.

8. Intelligent warehouse management: Through material bar coding, material IQC inspection, material collection, material delivery, material return, scrap, allocation, inventory and other efficient operations are carried out.

*Through the digitization of on-site manufacturing, a transparent real-time electronic display is formed. Display various Electronic display screen in turn through the slide mode, provide predictable data information, and grasp the production status in real time, Daily, hourly, weekly and monthly reports and analysis throughout the plant provide data support for daily production operations.

*Query data at the meeting or in real time, automatically send electronic reports by email according to the order number or based on the production situation, can determine the completion rate according to the set standard production capacity, and issue an unfinished reminder.

MES can be divided into three versions. You can choose different versions according to your own needs to achieve docking with different devices to achieve the scope of management. You can also choose the most basic version, gradually improve it, and upgrade.

1. Standard Edition: Including System Management, Basic Modeling, Warehouse Management, Production Management, Quality Management, Report Electronic Display Screen, a total of 6 groups of functions and 33 modules, mainly used for production line management.

2. Premium Edition: Including System Management, Basic Modeling, Warehouse Management, Production Management, Quality Management, Report Electronic Display Screen, a total of 6 groups of functions and 50 modules, mainly used for production line management, warehouse in and out material management.

3. Enterprise Synergistic Version: Including System Management, Supplier Collaboration, Basic Modeling, Warehouse Management, Production Management, System Integration, Quality Management, Report Electronic Display Screen, a total of 8 groups of functions and 65 modules, mainly used for the internal operation of the entire company and the management of external suppliers.

| Module | Product Description | Standard | Premium | Synergistic |

| System Management | Organizational Structure | √ | √ | √ |

| User Management | √ | √ | √ | |

| Role Management | √ | √ | √ | |

| Menu Management | √ | √ | √ | |

| Email Push | √ | √ | √ | |

| Basic Modeling | Factory Resources | √ | √ | √ |

| Business Relationship | √ | √ | √ | |

| Bar Code Rules | √ | √ | √ | |

| Tag Management | √ | √ | √ | |

| Error Code Library | √ | √ | √ | |

| Process Modeling | √ | √ | √ | |

| Standard Working Hours | √ | √ | √ | |

| Personnel Settings | √ | √ | √ | |

| Process Settings | √ | √ | √ |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

* In addition to the main equipment, there are peripheral equipment configured by the main equipment.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 25 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 25 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

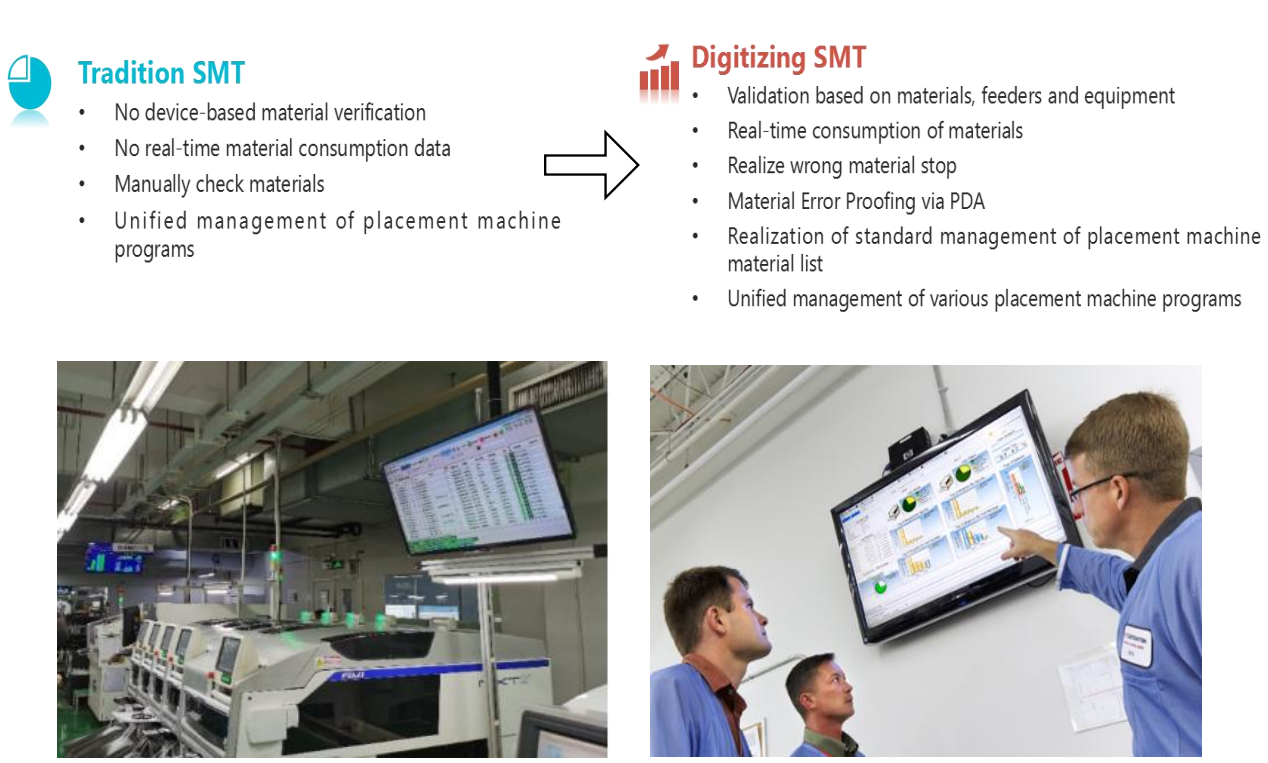

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

A Manufacturing Execution System (MES) is a computerized system used in manufacturing environments to monitor, manage, and control various aspects of the production process. MES software and hardware solutions are designed to bridge the gap between enterprise-level systems (such as Enterprise Resource Planning or ERP systems) and the shop floor, helping manufacturers optimize their operations and improve production efficiency.

Key functions and features of MES typically include:

Real-time data collection: MES systems gather data from various sources on the shop floor, including machines, sensors, and manual input, providing real-time information on production status.

Work order management: MES helps schedule and prioritize work orders, ensuring that production resources are utilized efficiently.

Process monitoring and control: MES monitors the manufacturing process, tracking factors like machine status, quality control, and resource allocation to maintain consistency and quality.

Quality control and tracking: MES systems enable quality checks, inspections, and traceability of products, ensuring that products meet specified standards and are traceable throughout their lifecycle.

Inventory management: MES systems help manage raw materials, work-in-progress (WIP), and finished goods inventory levels, optimizing stock levels and reducing waste.

Labor and resource management: MES assists in assigning tasks to workers and machines, ensuring that the right resources are allocated to meet production goals.

Performance analytics and reporting: MES generates reports and dashboards that provide insights into production performance, downtime analysis, and other relevant KPIs to help management make data-driven decisions.

Integration with other systems: MES is often integrated with other enterprise systems like ERP, Product Lifecycle Management (PLM), and Supply Chain Management (SCM) to ensure data consistency and process synchronization.

MES systems play a crucial role in modern manufacturing, helping organizations streamline their operations, improve product quality, reduce lead times, and increase overall productivity. These systems are particularly important in industries where compliance and traceability are critical, such as pharmaceuticals, food and beverage, and aerospace, as well as in discrete manufacturing and process industries.

A Manufacturing Execution System (MES) is a computerized system used in manufacturing environments to monitor, manage, and control various aspects of the production process. MES software and hardware solutions are designed to bridge the gap between enterprise-level systems (such as Enterprise Resource Planning or ERP systems) and the shop floor, helping manufacturers optimize their operations and improve production efficiency.

Key functions and features of MES typically include:

Real-time data collection: MES systems gather data from various sources on the shop floor, including machines, sensors, and manual input, providing real-time information on production status.

Work order management: MES helps schedule and prioritize work orders, ensuring that production resources are utilized efficiently.

Process monitoring and control: MES monitors the manufacturing process, tracking factors like machine status, quality control, and resource allocation to maintain consistency and quality.

Quality control and tracking: MES systems enable quality checks, inspections, and traceability of products, ensuring that products meet specified standards and are traceable throughout their lifecycle.

Inventory management: MES systems help manage raw materials, work-in-progress (WIP), and finished goods inventory levels, optimizing stock levels and reducing waste.

Labor and resource management: MES assists in assigning tasks to workers and machines, ensuring that the right resources are allocated to meet production goals.

Performance analytics and reporting: MES generates reports and dashboards that provide insights into production performance, downtime analysis, and other relevant KPIs to help management make data-driven decisions.

Integration with other systems: MES is often integrated with other enterprise systems like ERP, Product Lifecycle Management (PLM), and Supply Chain Management (SCM) to ensure data consistency and process synchronization.

MES systems play a crucial role in modern manufacturing, helping organizations streamline their operations, improve product quality, reduce lead times, and increase overall productivity. These systems are particularly important in industries where compliance and traceability are critical, such as pharmaceuticals, food and beverage, and aerospace, as well as in discrete manufacturing and process industries.