DECAN S2

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

Advanced Chip shooter

The Decan Line maximizes productivity in connection with the T-solution, an optimized software for integrated management, and introduces stable quality.

DECAN S2 increases the speed/accuracy for the placement of microchips (03015)

Advance chip mounter

Fast & flexible pick and place machine

Multi-functional SMT placement

Fast flexible pick & place machine

| Model | DECAN S2 | DECAN F2 | DECAN L2 |

| Of Spindles | 2 Gantryx10 Spidles/ Head | 2 Gantryx10 Spidles/ Head | 2 Gantryx6 Spidles/ Head |

| Placement Speed | 92,000 CPH (Optimum) | 80,000 CPH (Optimum) | 56,000 CPH (Flying Vision,Optimum) |

| Vison | Flying Vision | Flying Vision Stage Vision (Optimun) | |

| Placement Accuracy | ±28μm Cpk≥1.0 | ±40μm Cpk≥1.0 | |

| Component Range | 03015 ~ 12mm(H10mm) | 0402(01005) ~ 16mm(H10mm) | 0402(01005) ~ 21mm(H12mm) |

| PCB Size | 50x40~510x460mm (standard) ~610x460mm(Option), ~740x460(Option) ~810x460mm(Option), ~1200x460(Option) | ||

| Conveyor Configurations | Standard : 1-2- 1 Option : 1-2-2/2-2-2/2-2-1/1-1-1 Factory Option : Single Conveyor (Jedec Tray 2ea) | ||

| Feeder Capacity | 120ea (8mm) | ||

| Power | Voltage : 3 phase AC200/208/220/240/380/415V ±10% Frequency : 50/60Hz Power Consumption : Max. 5.0kVA | ||

| Air Consumption | 50Nl/min | ||

| Weight | About 1,800kg | ||

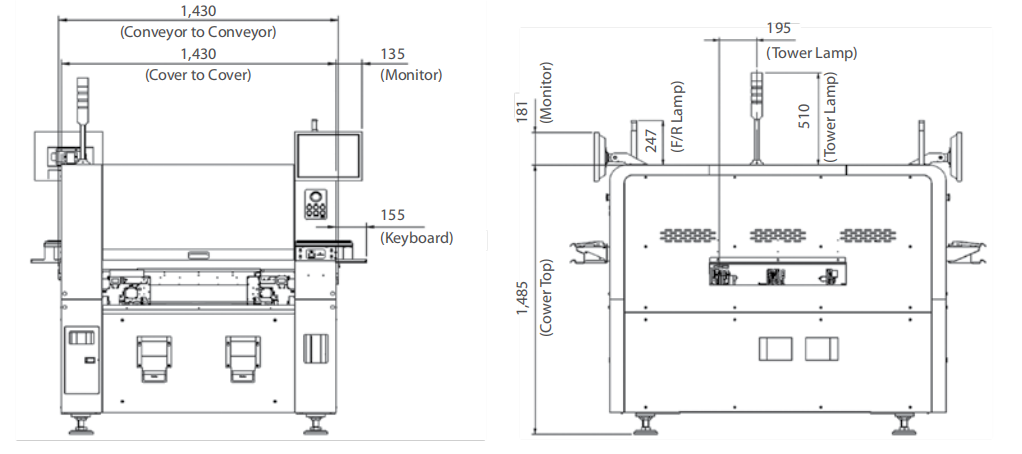

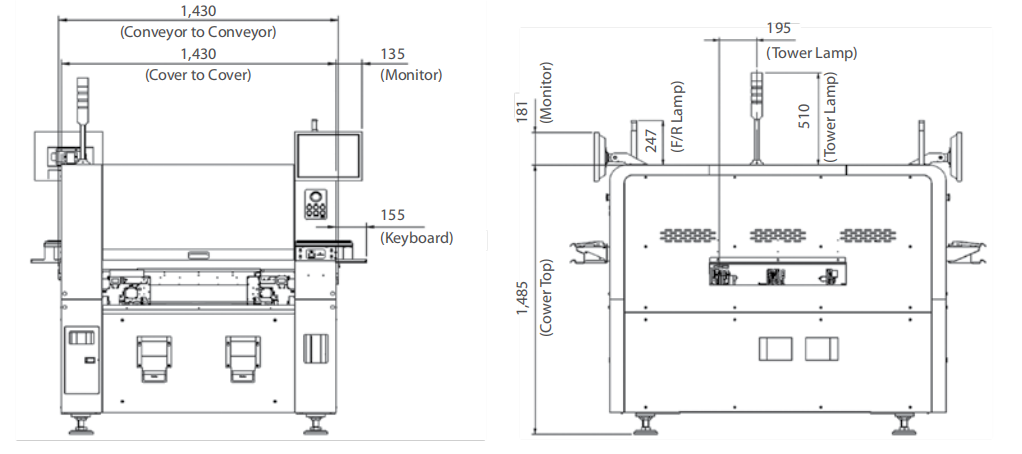

| External Dimensions (mm) | 1,430(L) x 1,740(D) x 1,485(H) | ||

* Under optimum condition of specified by HANWHA TECHWIN.

Advanced Chip shooter

The Decan Line maximizes productivity in connection with the T-solution, an optimized software for integrated management, and introduces stable quality.

DECAN S2 increases the speed/accuracy for the placement of microchips (03015)

Advance chip mounter

Fast & flexible pick and place machine

Multi-functional SMT placement

Fast flexible pick & place machine

| Model | DECAN S2 | DECAN F2 | DECAN L2 |

| Of Spindles | 2 Gantryx10 Spidles/ Head | 2 Gantryx10 Spidles/ Head | 2 Gantryx6 Spidles/ Head |

| Placement Speed | 92,000 CPH (Optimum) | 80,000 CPH (Optimum) | 56,000 CPH (Flying Vision,Optimum) |

| Vison | Flying Vision | Flying Vision Stage Vision (Optimun) | |

| Placement Accuracy | ±28μm Cpk≥1.0 | ±40μm Cpk≥1.0 | |

| Component Range | 03015 ~ 12mm(H10mm) | 0402(01005) ~ 16mm(H10mm) | 0402(01005) ~ 21mm(H12mm) |

| PCB Size | 50x40~510x460mm (standard) ~610x460mm(Option), ~740x460(Option) ~810x460mm(Option), ~1200x460(Option) | ||

| Conveyor Configurations | Standard : 1-2- 1 Option : 1-2-2/2-2-2/2-2-1/1-1-1 Factory Option : Single Conveyor (Jedec Tray 2ea) | ||

| Feeder Capacity | 120ea (8mm) | ||

| Power | Voltage : 3 phase AC200/208/220/240/380/415V ±10% Frequency : 50/60Hz Power Consumption : Max. 5.0kVA | ||

| Air Consumption | 50Nl/min | ||

| Weight | About 1,800kg | ||

| External Dimensions (mm) | 1,430(L) x 1,740(D) x 1,485(H) | ||

* Under optimum condition of specified by HANWHA TECHWIN.

FAQ:

1. What is the pick and place process in SMT?

The pick and place process in Surface Mount Technology (SMT) involves the automated placement of surface mount components (SMDs) onto printed circuit boards (PCBs). Pick and place machines precisely pick up components and position them on the PCB before soldering.

2. What are the stages of SMT reflow?

SMT reflow soldering typically involves several stages: preheating to remove moisture, a gradual temperature ramp-up, a peak temperature phase where solder melts, and finally, cooling to solidify the solder joints.

3. What is the temperature of SMT reflow?

The temperature of SMT reflow soldering varies depending on the solder paste used and the components on the PCB. Generally, peak temperatures range from 215°C to 260°C (419°F to 500°F).

4. How can I improve my SMT process?

To enhance your SMT process, consider optimizing solder paste application, ensuring accurate component placement, monitoring temperature profiles, conducting regular equipment maintenance, and implementing quality control measures like automated inspections.

FAQ:

1. What is the pick and place process in SMT?

The pick and place process in Surface Mount Technology (SMT) involves the automated placement of surface mount components (SMDs) onto printed circuit boards (PCBs). Pick and place machines precisely pick up components and position them on the PCB before soldering.

2. What are the stages of SMT reflow?

SMT reflow soldering typically involves several stages: preheating to remove moisture, a gradual temperature ramp-up, a peak temperature phase where solder melts, and finally, cooling to solidify the solder joints.

3. What is the temperature of SMT reflow?

The temperature of SMT reflow soldering varies depending on the solder paste used and the components on the PCB. Generally, peak temperatures range from 215°C to 260°C (419°F to 500°F).

4. How can I improve my SMT process?

To enhance your SMT process, consider optimizing solder paste application, ensuring accurate component placement, monitoring temperature profiles, conducting regular equipment maintenance, and implementing quality control measures like automated inspections.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT