I.C.T-L24(Customized)

I.C.T

| Availability: | |

|---|---|

| Quantity: | |

Introduction

L series lead-free reflow oven I.C.T’s mature product after years of market testing.L Series Reflow oven has maintained a larger share of the market for many years. Its unparalleled heating performance and temperature control system meets the requirements of various welding processes, It is I.C.T’s crystallization of years technical research and development.

L Series Lead-free reflow is high-end reflow products committed to keeping up with market demand to enhance customers competitiveness.Its new design concept fully meets the needs of increasingly diverse processes, And considering the future direction of the industry, entirely suitable for communications, automotive electronics, home appliances, computers and other consumer electronic products .

Feature

1.Control System: PC + Siemens PLC control system,accurate temperature control and more stable,ensures temperature stability rate to be more than 99.99%.

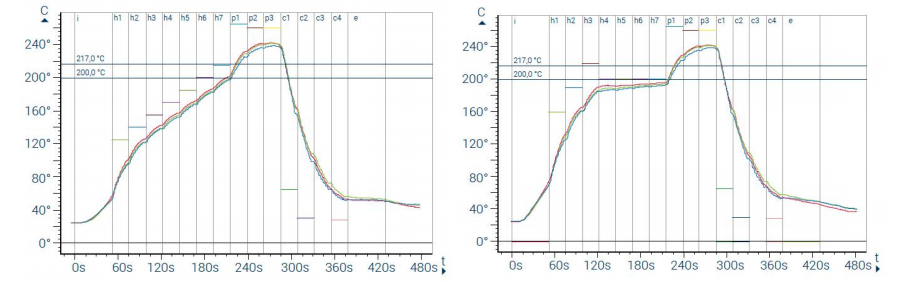

2.Hot air system: first-class heating module, the best temperature zone interval design makes optimum temperature uniformity and repeat.The effective utilization and thermal compensation efficiency,it needs less than 20 minutes from temperature control accuracy ± 1 ℃ambient temperature to a temperature stabilization .

3.Monitoring Software:Windows interface, traditional and simplified Chinese and English online free switch, and operator password management, easy to operate.Operation records, temperature curve measurement and analysis functions, virtual simulation, fault self-diagnosis, process monitoring, automatic generate and save process control documents, substrate transport dynamic display.

4.Cooling System: new cooling zone, quick and easy adjustment, easily reach the cooling requirements of different slopes.

5.Temperature protection:I.C.T using third-party over-temperature protection, multiple layers protection to ensure safe operation.

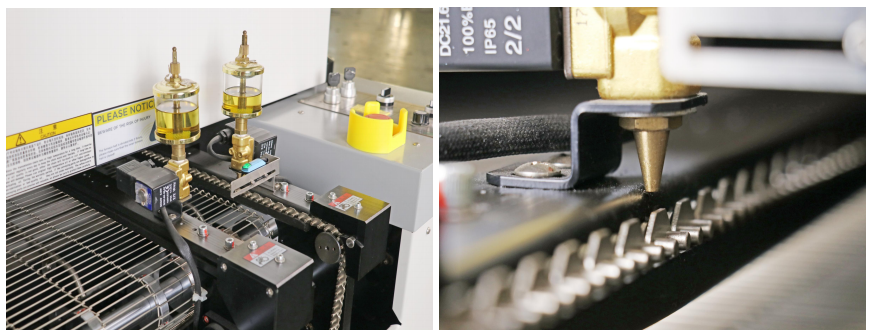

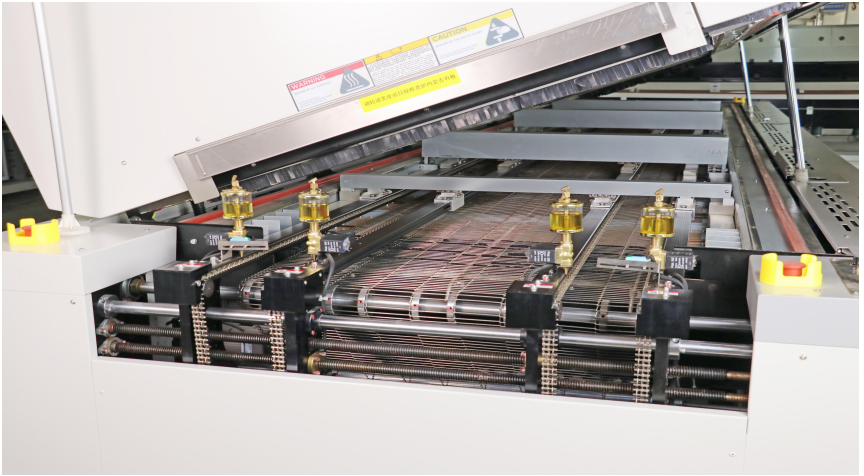

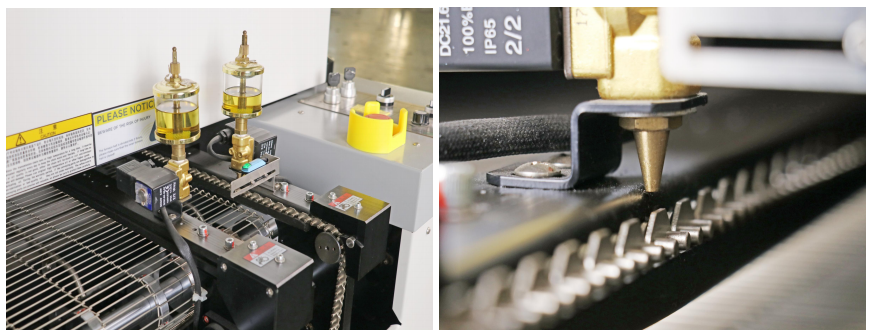

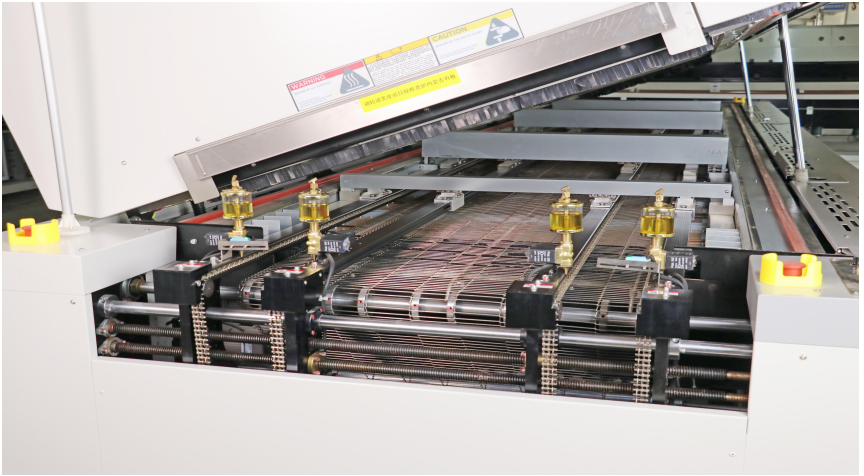

1. The transportation method of mesh belt + chain is compatible with most PCBs and can meet more needs;

2. The overall segmented guide rail and multi-cantilever structure ensure the parallelism and stability of the guide rail;

3. High-temperature resistant lubricating oil, standard computer-controlled filling cycle, no manual maintenance required;

4. Independent frequency converter, imported Panasonic motor, computer closed-loop control of transmission speed, deviation within ±2%;

5. Option:dual rails with independent control of each rail’s speed;

6. The special spring-type chain tensioning device automatically adjusts the chain tightness to ensure that the chain will not get stuck;

7. Independent rail width adjustment, optional central support.

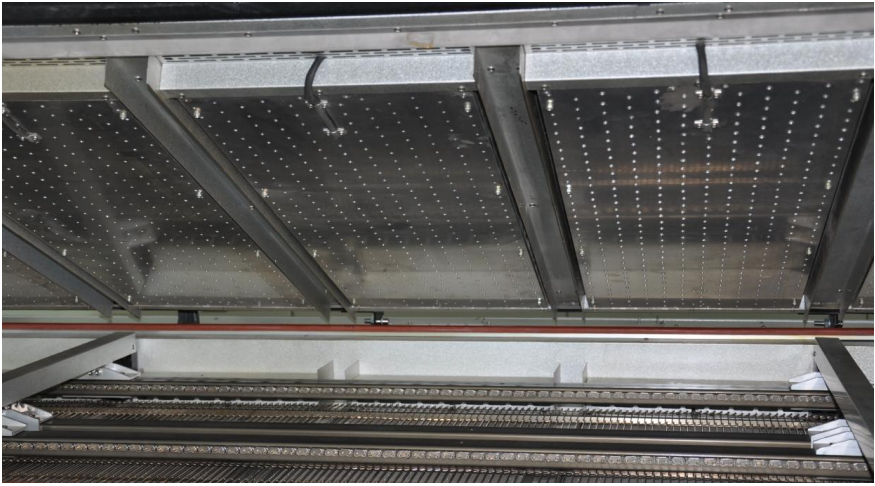

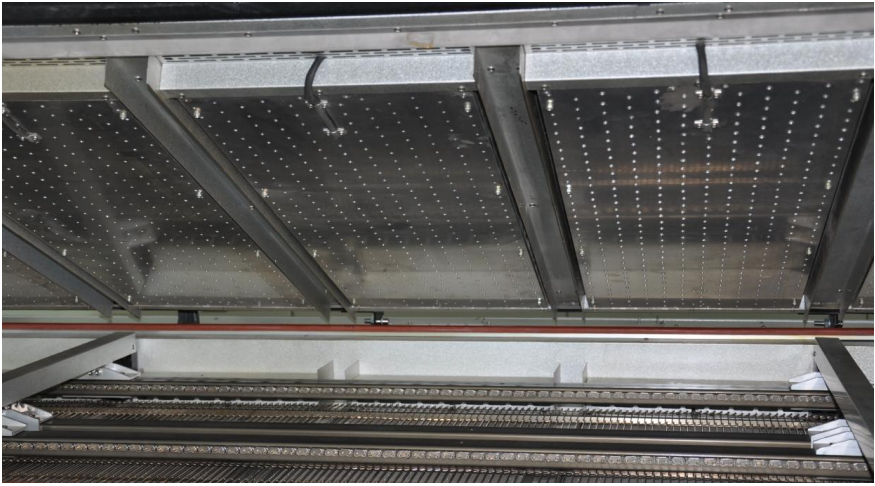

1. Imported high-temperature-resistant long-axis motor, with independent inverter control of upper and lower temperature zones, supporting stepless speed regulation from 0 to 3000 speeds;

2. Specially made long-life winding heater with high thermal efficiency and sensitivity and small thermal inertia;

3. Efficiently accelerates the air duct to provide sufficient circulating air volume;

4. The rectifier board is made of high-quality imported aluminum-zinc plate, which has thermal compensation and thermal recovery of PCB, high thermal efficiency and better uniformity;

5. PID+SSR temperature control method, the temperature control accuracy reaches ±1℃

6. Each zone is independently controlled, and the PID+SSR temperature control method can better meet different temperature curves.

If you want to customized 24 Zones PCB SMT Reflow Oven Machine, please contact us >>

Model | L8 | L10 |

Dimension (L*W*H)mm | 5000x1300x1530 | 5800x1300x1530 |

Weight | Approx. 2100KG | Approx. 2315KG |

Number Of Heating Zones | Up8/Bottom8 | Up10/Bottom10 |

Length Of Heating Zones | 3110mm | 3892mm |

Rail Width Adjustment | Manual adjustment (Option: Automatic) | |

Exhaust Volume | 10M3/min*2 Exhausts | |

Control System | PLC+Computer | |

Temperature Control Method | PID + SSR | |

Transmission Agent | Chain + Mesh | |

Electric Supply Required | 5 Wire System 3P, N, PE 380 VAC ± 5%, 50 Hz. Other voltages upon request | |

Power For Warm Up | 64KW | 80KW |

Power Consumption | 10KW | 12KW |

Warming Time | Approx.25 minute | |

Temp. Setting Range | Room Temp.-- 300°C | |

Conveyor Height | 900+/-20mm | |

Conveyor Speed Range | 300~2000mm/mi | |

Fixed Rail Side | Front Fixed (Option:Rear Fixed) | |

Cooling Method | Forced-Air Motor and fan (Standard) | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

Introduction

L series lead-free reflow oven I.C.T’s mature product after years of market testing.L Series Reflow oven has maintained a larger share of the market for many years. Its unparalleled heating performance and temperature control system meets the requirements of various welding processes, It is I.C.T’s crystallization of years technical research and development.

L Series Lead-free reflow is high-end reflow products committed to keeping up with market demand to enhance customers competitiveness.Its new design concept fully meets the needs of increasingly diverse processes, And considering the future direction of the industry, entirely suitable for communications, automotive electronics, home appliances, computers and other consumer electronic products .

Feature

1.Control System: PC + Siemens PLC control system,accurate temperature control and more stable,ensures temperature stability rate to be more than 99.99%.

2.Hot air system: first-class heating module, the best temperature zone interval design makes optimum temperature uniformity and repeat.The effective utilization and thermal compensation efficiency,it needs less than 20 minutes from temperature control accuracy ± 1 ℃ambient temperature to a temperature stabilization .

3.Monitoring Software:Windows interface, traditional and simplified Chinese and English online free switch, and operator password management, easy to operate.Operation records, temperature curve measurement and analysis functions, virtual simulation, fault self-diagnosis, process monitoring, automatic generate and save process control documents, substrate transport dynamic display.

4.Cooling System: new cooling zone, quick and easy adjustment, easily reach the cooling requirements of different slopes.

5.Temperature protection:I.C.T using third-party over-temperature protection, multiple layers protection to ensure safe operation.

1. The transportation method of mesh belt + chain is compatible with most PCBs and can meet more needs;

2. The overall segmented guide rail and multi-cantilever structure ensure the parallelism and stability of the guide rail;

3. High-temperature resistant lubricating oil, standard computer-controlled filling cycle, no manual maintenance required;

4. Independent frequency converter, imported Panasonic motor, computer closed-loop control of transmission speed, deviation within ±2%;

5. Option:dual rails with independent control of each rail’s speed;

6. The special spring-type chain tensioning device automatically adjusts the chain tightness to ensure that the chain will not get stuck;

7. Independent rail width adjustment, optional central support.

1. Imported high-temperature-resistant long-axis motor, with independent inverter control of upper and lower temperature zones, supporting stepless speed regulation from 0 to 3000 speeds;

2. Specially made long-life winding heater with high thermal efficiency and sensitivity and small thermal inertia;

3. Efficiently accelerates the air duct to provide sufficient circulating air volume;

4. The rectifier board is made of high-quality imported aluminum-zinc plate, which has thermal compensation and thermal recovery of PCB, high thermal efficiency and better uniformity;

5. PID+SSR temperature control method, the temperature control accuracy reaches ±1℃

6. Each zone is independently controlled, and the PID+SSR temperature control method can better meet different temperature curves.

If you want to customized 24 Zones PCB SMT Reflow Oven Machine, please contact us >>

Model | L8 | L10 |

Dimension (L*W*H)mm | 5000x1300x1530 | 5800x1300x1530 |

Weight | Approx. 2100KG | Approx. 2315KG |

Number Of Heating Zones | Up8/Bottom8 | Up10/Bottom10 |

Length Of Heating Zones | 3110mm | 3892mm |

Rail Width Adjustment | Manual adjustment (Option: Automatic) | |

Exhaust Volume | 10M3/min*2 Exhausts | |

Control System | PLC+Computer | |

Temperature Control Method | PID + SSR | |

Transmission Agent | Chain + Mesh | |

Electric Supply Required | 5 Wire System 3P, N, PE 380 VAC ± 5%, 50 Hz. Other voltages upon request | |

Power For Warm Up | 64KW | 80KW |

Power Consumption | 10KW | 12KW |

Warming Time | Approx.25 minute | |

Temp. Setting Range | Room Temp.-- 300°C | |

Conveyor Height | 900+/-20mm | |

Conveyor Speed Range | 300~2000mm/mi | |

Fixed Rail Side | Front Fixed (Option:Rear Fixed) | |

Cooling Method | Forced-Air Motor and fan (Standard) | |

* I.C.T keeps working on quality and performance, specifications and appearance may be updated without particular notice.

FAQ:

Q: Why is it called reflow?

A: The term "reflow" in SMT (Surface Mount Technology) refers to the process of melting solder paste during soldering. This controlled melting and re-solidifying of solder create secure connections between components and PCBs.

Q: What are the components of a reflow oven?

A: A reflow oven in SMT typically includes heating elements, a conveyor system, thermal zones, temperature controllers, flux management, and exhaust systems. These components work together to ensure precise soldering during PCB assembly.

Q: How many times can you reflow solder?

A: To maintain the highest solder joint integrity and overall reliability in SMT, it is generally recommended to limit reflow soldering on a printed circuit board (PCB) to one or, at most, two times. Frequent reflows can subject components to thermal stress.

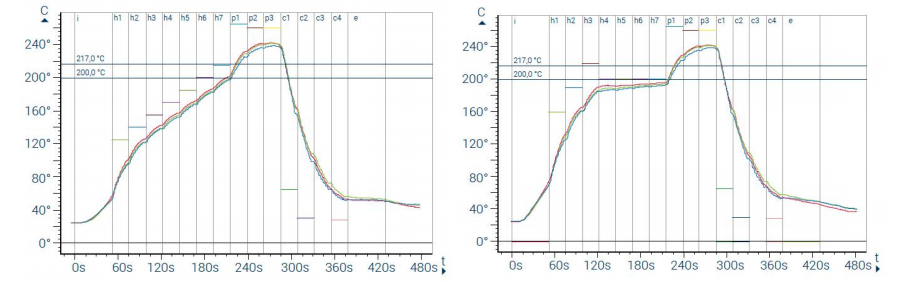

Q: What temperature is reflow solder?

A: The temperature used in reflow soldering in SMT varies based on the specific solder paste being used. Typically, temperatures range from approximately 200°C to 250°C (392°F to 482°F). These temperatures are carefully controlled to ensure proper solder joint formation during the reflow process.

FAQ:

Q: Why is it called reflow?

A: The term "reflow" in SMT (Surface Mount Technology) refers to the process of melting solder paste during soldering. This controlled melting and re-solidifying of solder create secure connections between components and PCBs.

Q: What are the components of a reflow oven?

A: A reflow oven in SMT typically includes heating elements, a conveyor system, thermal zones, temperature controllers, flux management, and exhaust systems. These components work together to ensure precise soldering during PCB assembly.

Q: How many times can you reflow solder?

A: To maintain the highest solder joint integrity and overall reliability in SMT, it is generally recommended to limit reflow soldering on a printed circuit board (PCB) to one or, at most, two times. Frequent reflows can subject components to thermal stress.

Q: What temperature is reflow solder?

A: The temperature used in reflow soldering in SMT varies based on the specific solder paste being used. Typically, temperatures range from approximately 200°C to 250°C (392°F to 482°F). These temperatures are carefully controlled to ensure proper solder joint formation during the reflow process.

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

I.C.T - Our Company

About I.C.T:

I.C.T is a leading provider of factory planning solution. We have 3 wholly-owned factories, providing professional consultation and services for global customers. We have more than 22 years of eletronic overall solutions. We not only provide a complete set of equipment, but also provide full range of technical support and services, and give customers more reasonable professional advice. We help many customersv to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are to set up factories in LED, TV, mobile phone, DVB, EMS and other indutries all over the world. We are trustworthy.

Exhibition

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

5. We Can Solve Any Question About SMT