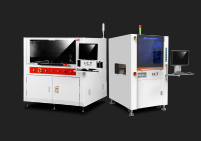

SMT (Surface Mount Technology ) is a process for manufacturing electronic circuits by mounting components directly on the surface of a printed circuit board (PCB). This is in contrast to the traditional through-hole technology, in which components are inserted through holes in the PCB and then soldered in place.

EMS companies provide a range of services, including:

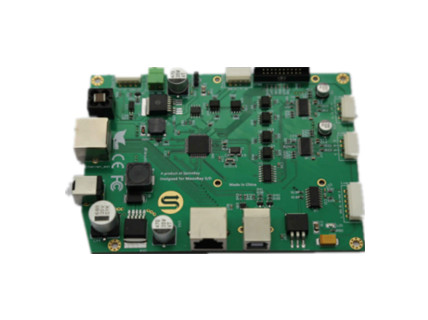

PCB design and manufacturing

Component sourcing and procurement

Assembly and testing

Quality control

Packaging and shipping

Return/repair services

EMS companies can offer a number of advantages over traditional manufacturing methods, including:

Reduced costs: EMS companies can often achieve economies of scale that are not possible for individual manufacturers.

Increased flexibility: EMS companies can often offer more flexibility in terms of production volumes and lead times.

Improved quality: EMS companies typically have more experience in manufacturing electronic components and assemblies, which can lead to improved quality.

Reduced risk: EMS companies can often share the risk of product development and manufacturing with their customers.

SMT is a key technology used by EMS companies. SMT allows for a higher density of components on the PCB, which can smaller and more compact devices. SMT components are also easier to solder than through-hole components, which can improved reliability. Additionally, SMT is a more automated process, which can reduced costs.

EMS companies that use SMT can offer a number of advantages over their competitors, including:

Smaller and more portable devices: SMT allows for a higher density of components on the PCB, which can lead to smaller and more compact devices. This is especially important for mobile devices, such as smartphones and tablets.

Improved reliability and performance: SMT components are easier to solder than through-hole components, which can lead to improved reliability. Additionally, SMT is a more automated process, which can lead to reduced defects.

Reduced costs: SMT is a more cost-effective process than through-hole technology. This is due to the fact that SMT allows for a higher density of components on the PCB, which can lead to smaller and more compact devices. Additionally, SMT is a more automated process, which can lead to reduced labor costs.

-

If you are considering using EMS services, it is important to choose an EMS company that has experience in using SMT. SMT is a complex technology, and it is important to work with a company that has the expertise to ensure that your products are manufactured to the highest quality standards.

I.C.T as a fast-growing broader intelligent equipment solution provider with more than 25 years experience in SMT industry. It will make your factory smart.

More details, please Contact Us for free.

English

English