In the field of electronics manufacturing, maintaining a leading position requires the use of cutting-edge manufacturing technology. One step is surface mount technology (SMT) PCB assembly. PCB assembly plays a particularly important role in the production of modern electronic products in terms of optimizing efficiency and quality.

What is SMT PCB Assembly?

SMT PCB Assembly, short for Surface Mount Technology PCB Assembly, is a revolutionary method of assembling electronic components onto circuit boards. Unlike traditional through-hole assembly, SMT involves directly mounting components onto the board's surface, leading to enhanced precision and performance.

What is the benefits of SMT PCB Assembly?

Compact Designs: SMT allows for the placement of smaller components in tight spaces, enabling the creation of sleek and compact electronic devices.

High-Speed Production: The automated nature of SMT Assembly machines accelerates production, reducing lead times and meeting market demands efficiently.

Cost Efficiency: With reduced manual labor and material wastage, SMT Assembly offers cost-effective manufacturing solutions.

Improved Performance: The shorter paths between components in SMT assemblies lead to lower resistance and better electrical performance.

Versatility: SMT is compatible with a wide range of components, from microchips to passive elements, making it suitable for various applications.

What is the application of SMT PCB Assembly:

Consumer Electronics: From smartphones to smart appliances, SMT Assembly drives innovation in consumer electronics with its compact design capabilities.

Medical Instruments: The precision of SMT ensures reliability in medical equipment, critical for accurate diagnoses and patient care.

Automotive Technology: SMT-enabled electronics power modern vehicles, enhancing safety, connectivity, and energy efficiency.

Industrial Automation: SMT plays a vital role in manufacturing machinery, robotics, and industrial control systems.

Aerospace and Defense: The aerospace industry relies on SMT Assembly for rugged and reliable electronics in demanding environments.

SMT PCB Assembly stands as a transformative force in electronics manufacturing, fostering progress across industries. With its ability to create smaller, high-performance devices and streamline production processes, SMT Assembly is at the forefront of innovation. By embracing this technology, businesses can ensure their products remain competitive, efficient, and aligned with the ever-evolving electronics landscape.

I.C.T - Your Reliable Dearest Partner

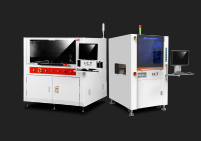

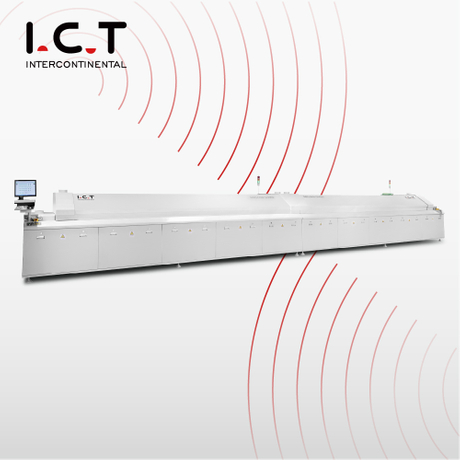

For you I.C.T can provide Full SMT Line Solution, DIP Line Solution and Coating Line Solution with best quality and service.

More information about I.C.T please Contact US at info@smt11.com

English

English