FAQ:

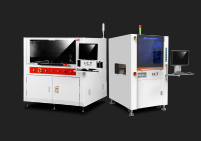

Q: How accurate are SMT pick-and-place machines in component placement?

A: These machines typically offer placement accuracy within the range of 20 to 50 micrometers (μm), ensuring precise assembly.

Q: What is the purpose of vision systems in pick-and-place machines?

A: Vision systems are used for component alignment and inspection, ensuring that components are placed accurately and detecting defects.

Q: Can SMT pick-and-place machines handle various component sizes and types simultaneously?

A: Yes, many machines have multiple placement heads and feeders to accommodate different component sizes and types in a single assembly process.

English

English