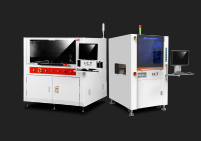

Q: What we can do for you?

A: Total SMT Machines and Solution, professional Technical Support and Service.

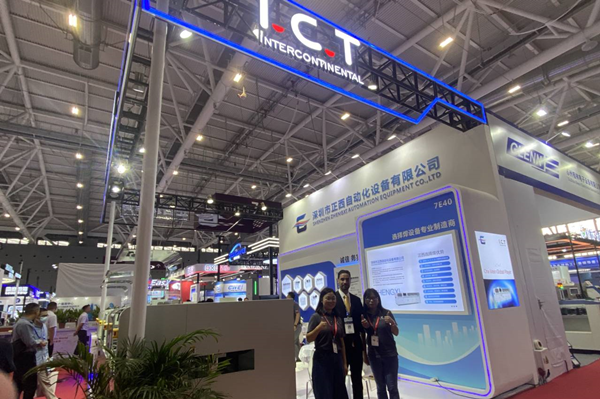

Q:Are you a trade company or a manufacturer?

A: OEM & ODM service are available.

Q: How can I optimize the throughput of my Yamaha pick and place machine?

A: To optimize throughput, ensure efficient feeder setup, use optimized placement strategies, and maintain the machine regularly for peak performance.

Q: Are Yamaha pick and place machines compatible with industry-standard CAD software?

A: Yes, Yamaha pick and place machines can often import PCB designs from industry-standard CAD software for precise component placement.

Q: What are the key factors affecting the accuracy of Yamaha pick and place machines?

A: Factors affecting accuracy include machine calibration, component quality, PCB flatness, and proper machine maintenance.

English

English