FAQ:

1. What is a chip mounter?

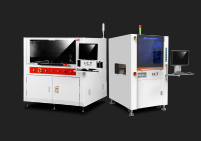

A chip mounter, also known as a pick-and-place machine, is a crucial component in Surface Mount Technology (SMT) assembly. It automates the precise placement of electronic components, including chips, onto printed circuit boards (PCBs) during the manufacturing process.

2. What is a surface mount chip?

A surface mount chip refers to an electronic component, often an integrated circuit or passive component like a resistor or capacitor, designed for surface mounting on a PCB. These chips have small, flat leads or terminals that make direct contact with the PCB's surface, eliminating the need for through-holes.

3. What is surface mount in electrical?

Surface mount in electrical engineering refers to a method of mounting electronic components directly onto the surface of a printed circuit board (PCB) without the need for traditional through-holes. This technology offers advantages such as smaller form factors, higher component density, and improved electrical performance.

4. What are the benefits of using surface mount technology (SMT)?

Surface mount technology (SMT) offers several advantages, including:

Compact Design: SMT components are smaller, enabling more compact and lightweight electronic devices.

Enhanced Performance: SMT components have shorter electrical paths, reducing signal distortion and improving performance.

Cost Efficiency: Automated SMT assembly reduces labor costs and increases production efficiency.

High Component Density: SMT allows for a higher density of components on PCBs, enabling more functionality in a smaller space.

5. What are common applications of surface mount technology (SMT)?

Surface mount technology finds extensive use in various industries, including:

Consumer Electronics: Such as smartphones, tablets, and laptops.

Automotive Electronics: For engine control units and infotainment systems.

Aerospace and Defense: In radar systems, communication equipment, and avionics.

Medical Devices: Including diagnostic equipment and wearable health devices.

LED Lighting: SMT is essential for efficient and compact LED lighting fixtures.

6. How does surface mount technology (SMT) differ from through-hole technology (THT)?

Surface mount technology (SMT) and through-hole technology (THT) are two PCB assembly methods. SMT involves mounting components on the PCB's surface, while THT involves inserting components through holes in the PCB and soldering them on the other side. SMT offers advantages in terms of miniaturization, automation, and cost-effectiveness, while THT may be preferred for rugged or high-current applications.

English

English